Glass Corner Piece Case Study

Process:SLA, Steel Tooling & Plastic Injection Molding

Part Size:100.6*100.6*45.67mm

Part Material:ABS

Tooling Details:P20/P20 Steel

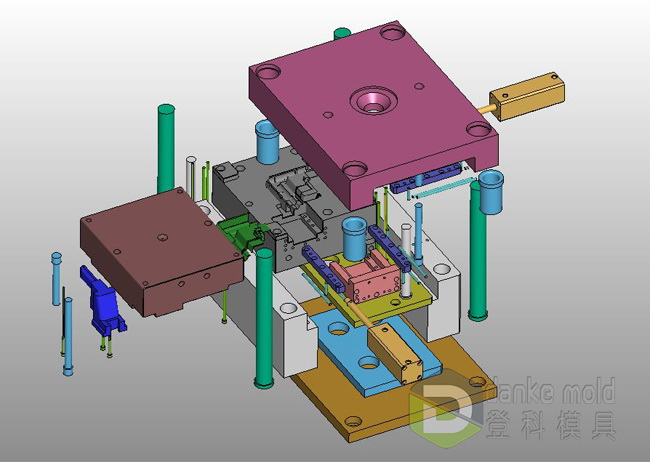

MUD Mold Base (common use in DM)

Single Cavity

2 Sliders for side actions

Tooling Life:50,000 cycles

Lead Time (T1 samples):20 days

Simple story of proceeding the project from prototype to production for Glass Corner Piece:

Jan 24th:

An old client came back with us for a cost idea of a Plastic Corner Piece at early design stage.

Jan 25th:

We got back the both the tooling and molding quotation with our client.

Jan 27th:

The client asked a DFM analysis of the part after CNY break, as we were on holiday already.

Anyway say ‘Gong Xi Fa Cai’ to each other at that time.J

Feb 3rd:

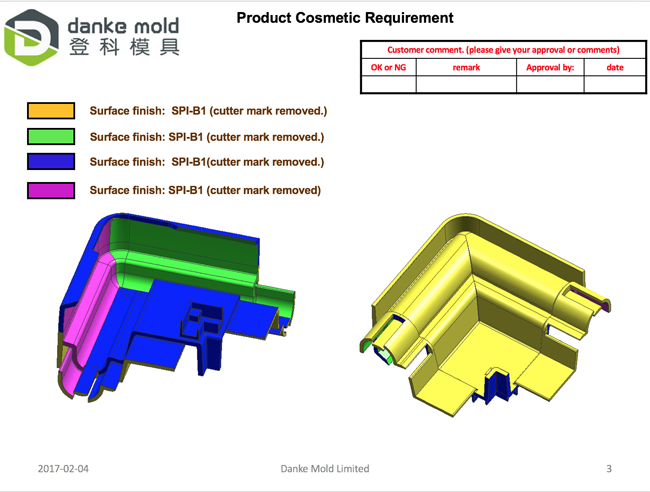

We came back from the CNY holiday, and got back the DFM the next day.

Feb 5th ~ 12th:

We discussed the tooling and molding manufacturing issue with our client.

Feb 16th:

We quoted 2 prototypes for our client.

Feb 27th:

The client confirmed us the prototype order by SLA process, but the drawing would need some adjustment.

Mar 1st:

The client confirmed the final drawing for us to kick off the SLA prototype.

Mar 3rd:

We shipped 2 SLA prototypes to our client.

Mar 14th:

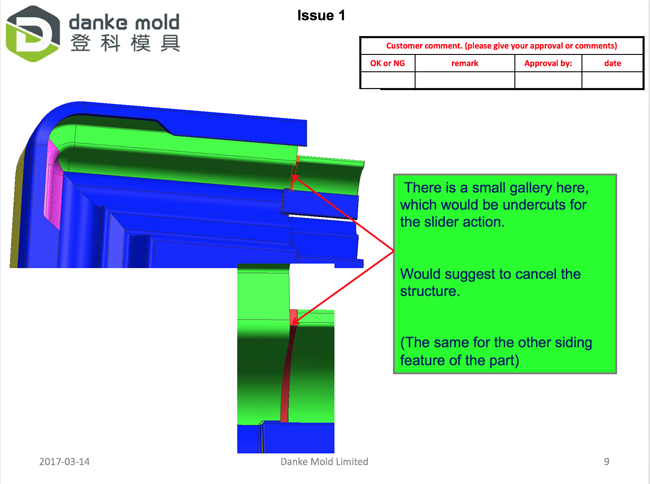

The client updated the 3D drawing again for design-for-manufacturing analysis.

Mar 15th ~ 23rd:

We worked with our client back and forth for solving the issues before proceed to tooling and injection molding.

Mar 27th:

;The client confirmed the tooling order to us to kick off the job.

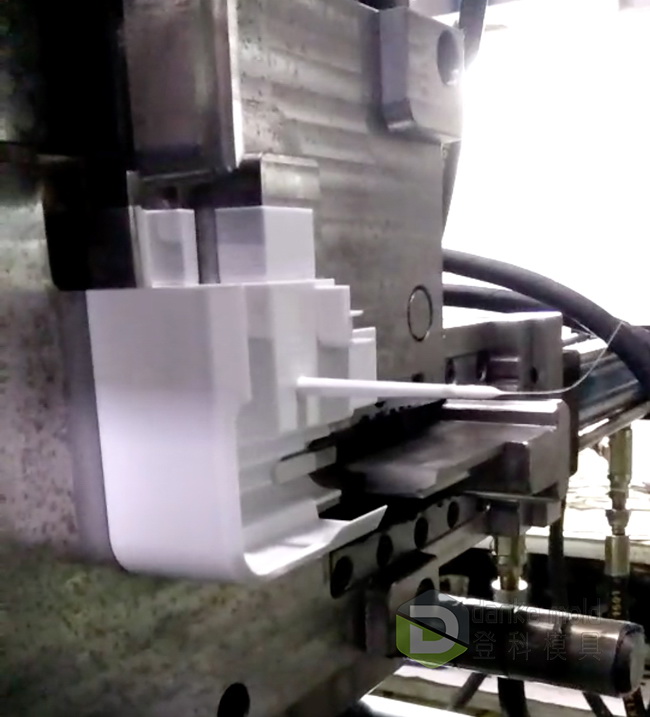

March 28th ~ April 17th:

Tool Building and Mold Trial for T1 samples.

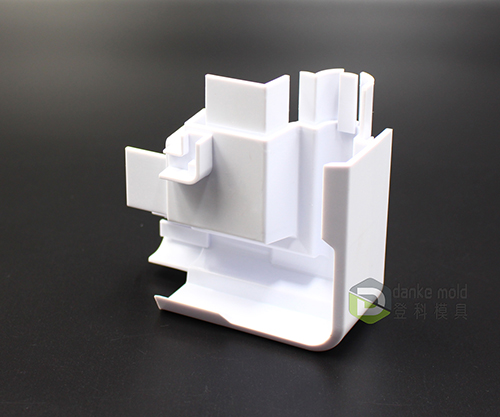

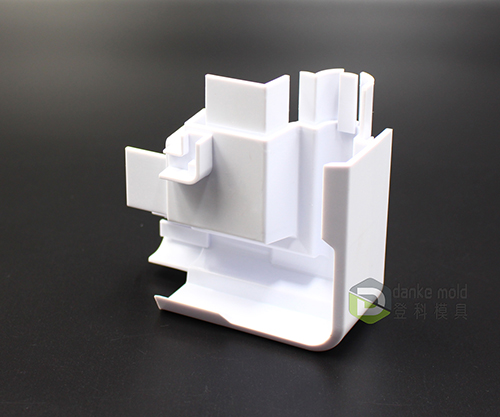

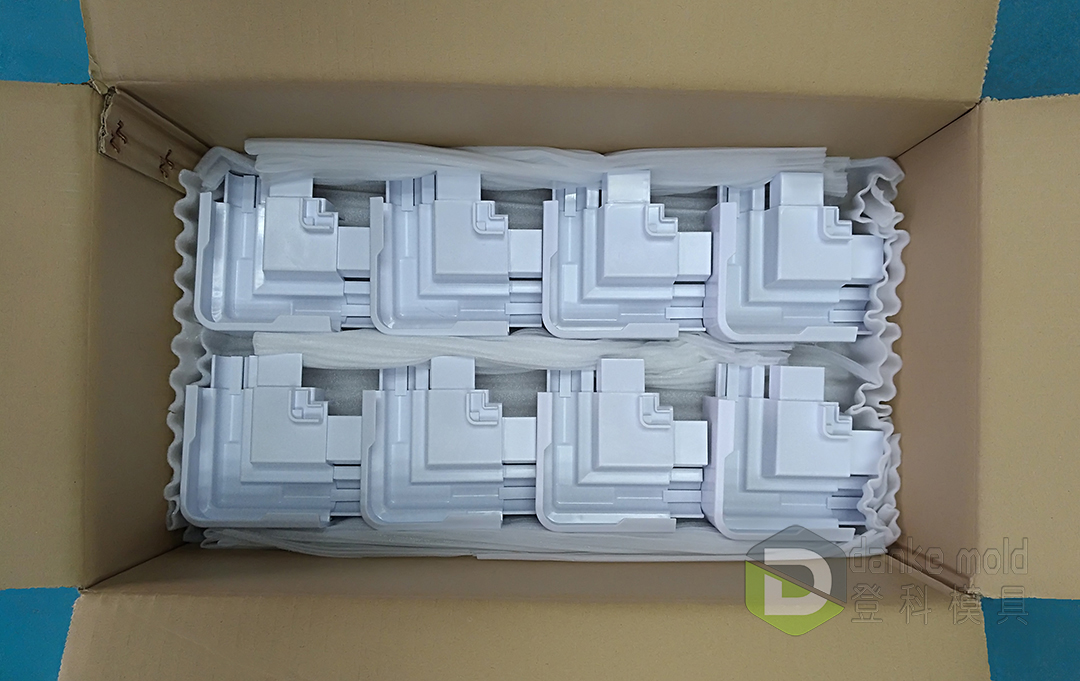

April 18th:

We shipped 10 pieces of T1 samples to our client.

April 21st:

The client got back with us that the samples received look very good.

They will get back to us again after get through all the necessary assembly trials in a few weeks.

Initial DFM

SLA Prototype

Finalized DFM

Tool Design

Tooling Machining

Samples Shipped