When it comes to the plastic injection molding is concerned, you would find that there are several parameters that you would find much exciting and innovative. With the best in class high tech equipment and a superior quality of the end products, you would find that there is several injection molding techniques that can prove to be quite much interesting and quite practical.

There are several plastic molding techniques that you would find being utilised by the different plastic mold companies. It should be noticed that each of the applications will require a specific and unique manufacturing process. Pick the right manufacturing process depending on your individual manufacturing requirements.

A few of the techniques that a plastic mold making company can indulge in can include

Blow molding

If you are into creating hollow interiors, the blow molding should be the right choice that you would prefer. This can include the manufacturing of water bottles, ink bottles or similar other vessels and prodcuts that are hollow from inside. Jars, storage containers, and similar other products can also be a good option to use blow molding. It can be the best process for manufacturing one piece hollow objects. It can also be a good choice for the manufacture of the prodcuts that require high volume production.

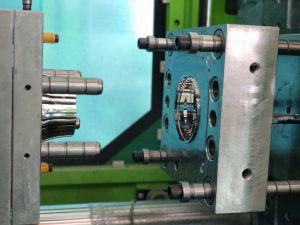

Injection molding

This is one of the most popular techniques and is used for manufacturing superior-quality and high-volume products. This has been rated as one of the most versatile molding techniques and manufacturing processes that you might have come across. So many molding companies are dependent on the plastic injection molding process. The injection molding has been known for the best medical field. You would find the process being in use in areas such as automotive, aviation, transportation, and aerospace industries.You would also find it offering you different types of plastic resins and additives.

Extrusion molding

This is the custom extrusion molding that lets you achieve one of the excellent experiences. It can be helpful in offering you in creating long, hollow, and formed products. The plastic molding technique is used in the manufacture of pipes, tubing, and drinking straws. Extrusion process makes use of a die instead of a mold. The extrusion molding is one of the excellent choices for custom plastic molding.

Compression molding

Compression molding is yet another practical option especially for use with large finished products. The process involves the passage of the heated plastic material moving inside a heated mold. The material is now compressed to the desired shape. This has been one of the prominent manufacturing processes used with thermosetting resins, reinforced plastics, fiberglass, and other high-strength compounds.

Well, those were just a few of the best molding techniques that you would find quite unique and practical in their own right. Each of these processes hold their own standard and have their own pros and cons. Depending on which process is more suited for your projects, you can choose the right plastic molding technique that you would perhaps find quite impressive for your needs.