by Joe Deng | Jan 26, 2019 | Blog

How Danke Mold helps quick-turn Injection Molding Product designs and engineers are always eager to make their ideas into reality as fast as possible. At early stage of product development, prototype or small volume production parts would be made by SLA, CNC...

by Danke Mold | Jan 24, 2019 | Blog, Rapid Prototyping

Some practical notes about Rapid Prototyping-Sectioning When we running rapid prototype projects, which I mean includes CNC machining, SLA and vacuum casting projects, there’s various of “rules” that we should know. These “rules” are actually indications to help us to...

by Joe Deng | Jan 23, 2019 | Blog

How to find a Quick-Turn Injection Molding manufacturer At early stage of product development, a good quick-turn injection molding manufacturer can help designers or engineers, develop their products rapidly, and in cost efficiency. Rapid tooling and quick...

by Joe Deng | Jan 21, 2019 | Blog, Rapid tooling & Injection molding

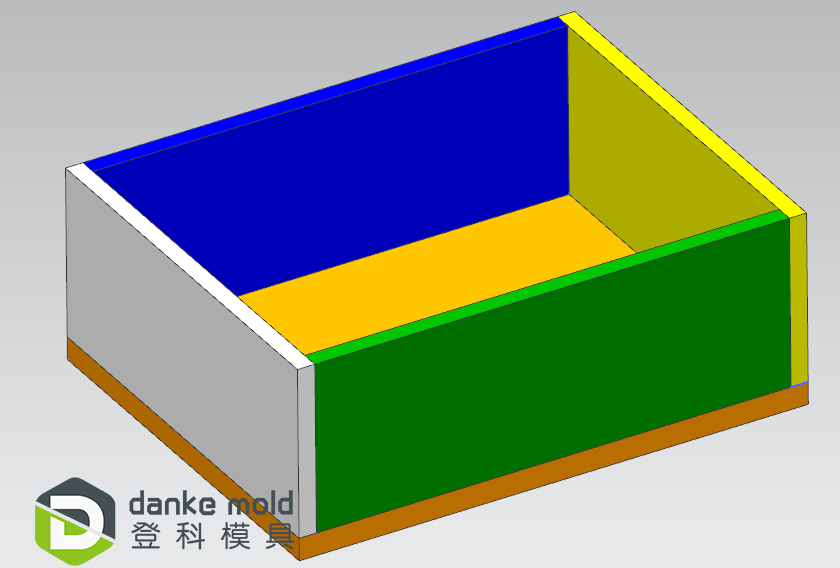

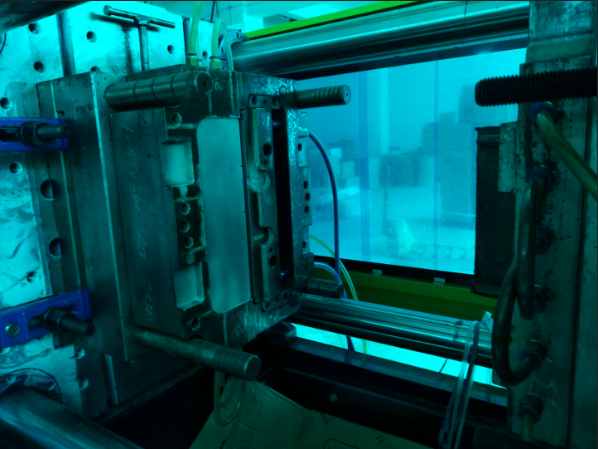

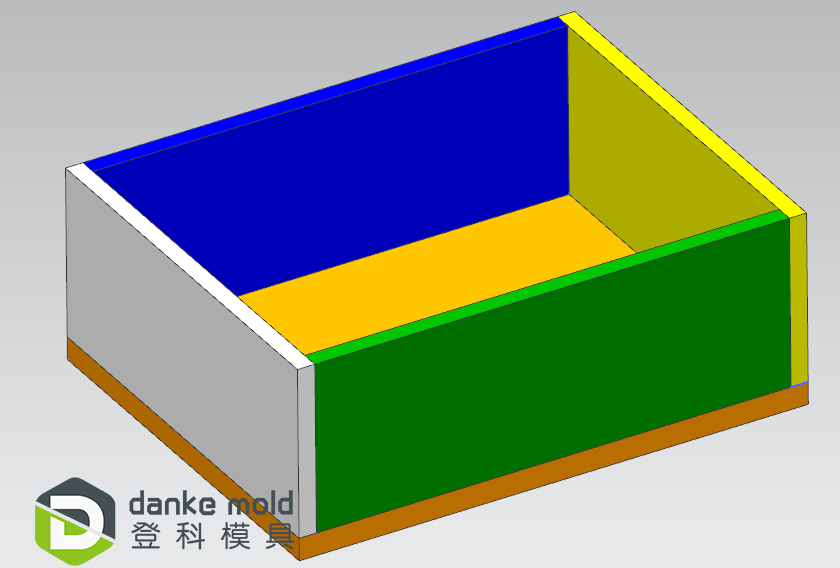

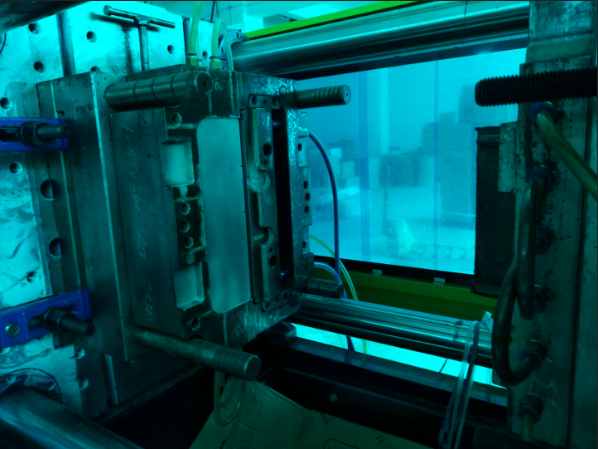

How to have cost efficiency Injection Molding Prototypes We learned that there are a lot of advantages of using injection molding for prototype making. For example: Real part material as volume molding production; Real surface finish as volume molding...

by Danke Mold | Jan 18, 2019 | Blog, Rapid tooling & Injection molding

What’s difference between Rapid Tooling and Production Mold From application difference of plastic injection molds, we can roughly separate them into rapid tooling, and production injection mold. Rapid tooling is mainly for early stage of product...