by Danke Mold | Nov 29, 2024 | Plastic Injection Molding

Injection molding is a complex manufacturing technique in which a special hydraulic or electric equipment melts, injects, and sets plastic into a metal mold to form it. Plastic injection molding is the most common technique for producing components because:...

by Danke Mold | Nov 27, 2024 | Vacuum Casting

Manufacturing businesses that value accuracy and quality must produce high-quality components. Medical device manufacturers, aviation engineers, and consumer product designers are always searching for flexible molding solutions to enable high-quality product design....

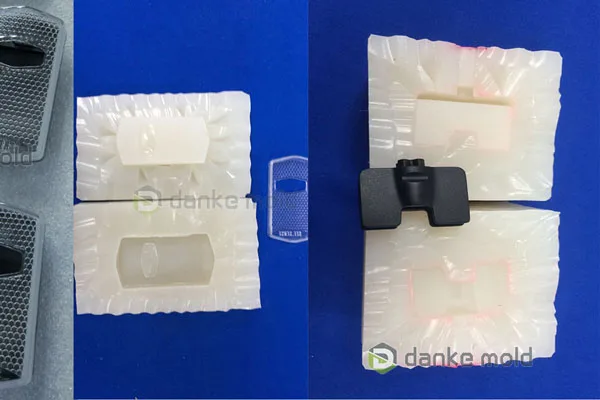

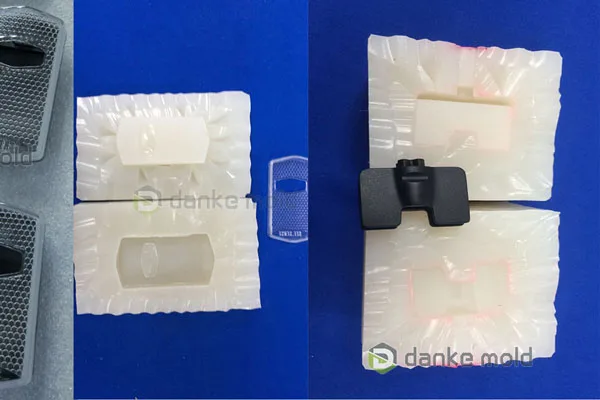

by Danke Mold | Nov 25, 2024 | Vacuum Casting

Many businesses employ silicone molding. Silicone molds make high-tech, durable, and complicated consumer and industrial items. This article covers silicone molding types, applications, benefits, disadvantages, and technique. Silicone Molding Molds for components or...

by Danke Mold | Nov 21, 2024 | Rapid Prototyping

In today’s fast-paced industrial world, speed and efficiency drive digital innovation. Manufacturers can build prototypes and production-ready tools faster and cheaply via rapid tooling (RT). Fast prototyping and standard manufacturing are transforming how firms...

by Danke Mold | Nov 18, 2024 | Vacuum Casting

It’s not too difficult to make a silicone mold. The item you wish to duplicate must first be created as a master model. A range of materials, including clay, wax, and even pre-existing objects, can be used for this. For the avoidance of air bubbles, make sure to...