by Danke Mold | Jul 31, 2025 | Plastic Injection Molding

Microplastic medical component molding plays a crucial role in producing precise, small parts essential for modern healthcare devices. Using injection molding, manufacturers can create components with extremely tight tolerances, often measured in millimeters or...

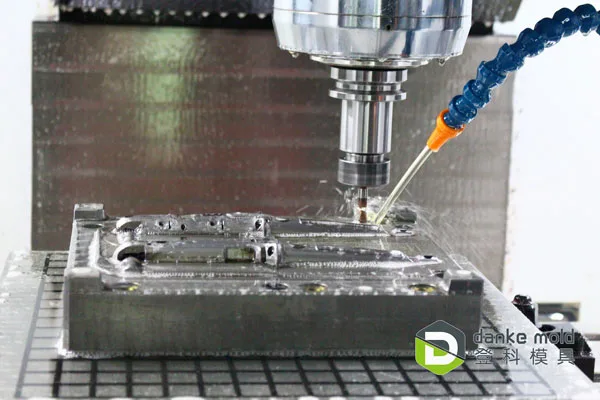

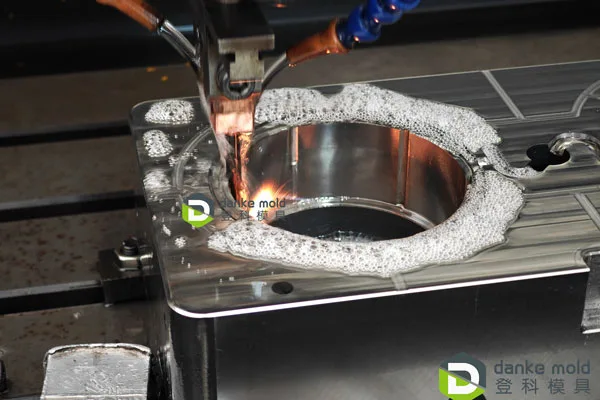

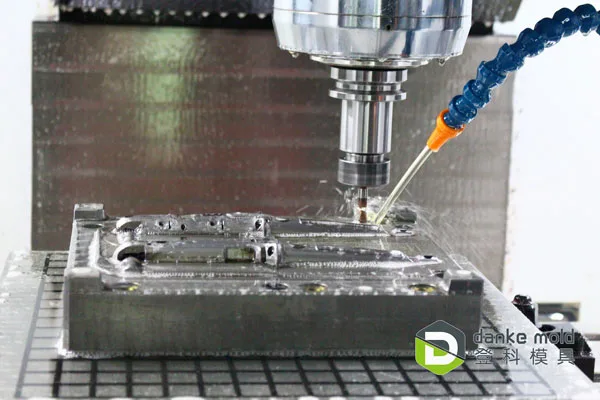

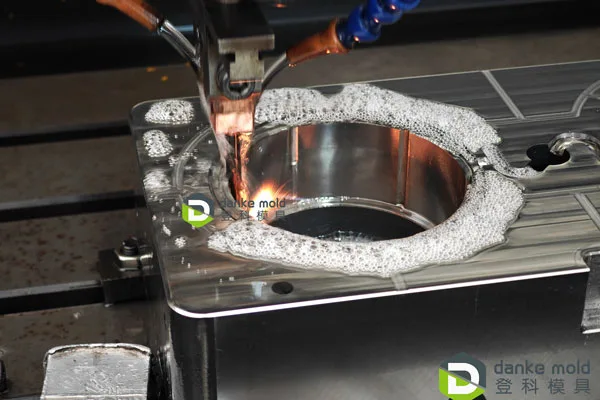

by Danke Mold | Jul 28, 2025 | CNC Machining

When you need aerospace components with complex shapes and tight tolerances, 5-axis CNC machining offers a precise and efficient solution. This technology enables simultaneous movement across five axes, allowing you to create intricate parts in a single setup without...

by Danke Mold | Jul 25, 2025 | CNC Machining

Manufacturing has reached a turning point. Traditional CNC machining methods are joining forces with artificial intelligence to produce parts that meet demanding quality standards. This fusion creates manufacturing processes that adapt, learn, and improve with each...

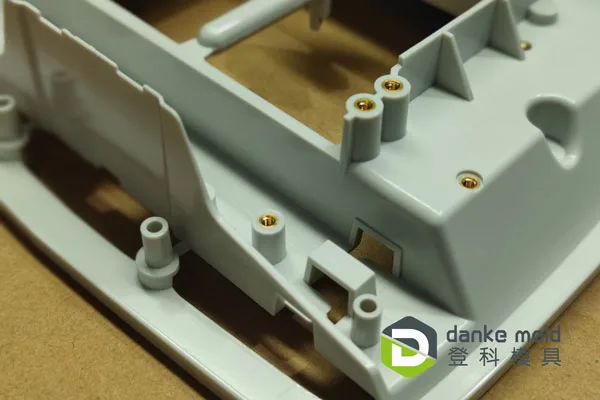

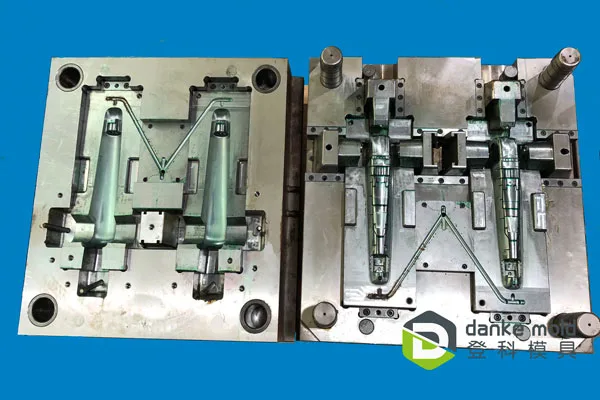

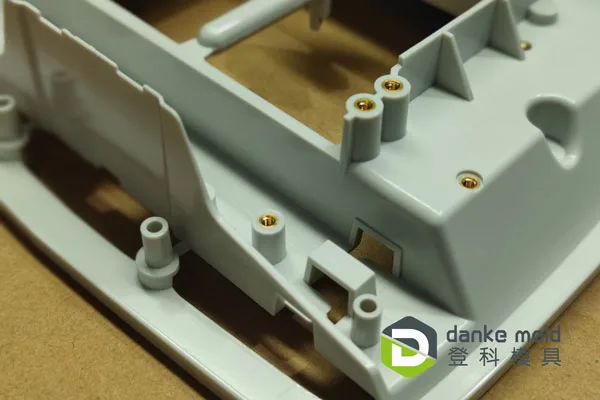

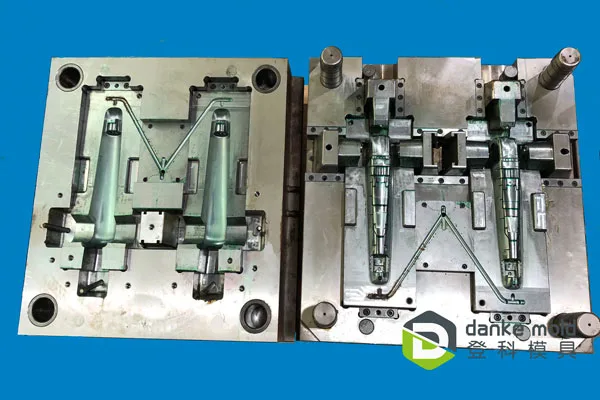

by Danke Mold | Jul 21, 2025 | Insert Molding

In today’s manufacturing, many products feature a combination of metal and plastic components. Among various methods to achieve this, insert molding is the most widely used. Its popularity stems mainly from its cost efficiency compared to other insertion techniques....

by Danke Mold | Jul 18, 2025 | Compression Molding

Compression molding is a widely used manufacturing process that provides an efficient and cost-effective way to produce high-quality plastic and composite parts. The technique is particularly popular in industries such as automotive, aerospace, electronics and...