by Danke Mold | Feb 22, 2023 | Blog, Industry information, Rapid tooling & Injection molding

Plastic Injection molding is a very traditional industry, it needs high investment for equipment like CNC machine, milling machine, injection molding machine and overhead crane, etc. and need to hire many skilled masters and workers. In the past, about from 1990s to...

by Danke Mold | Feb 14, 2023 | Blog, Industry information, Rapid tooling & Injection molding

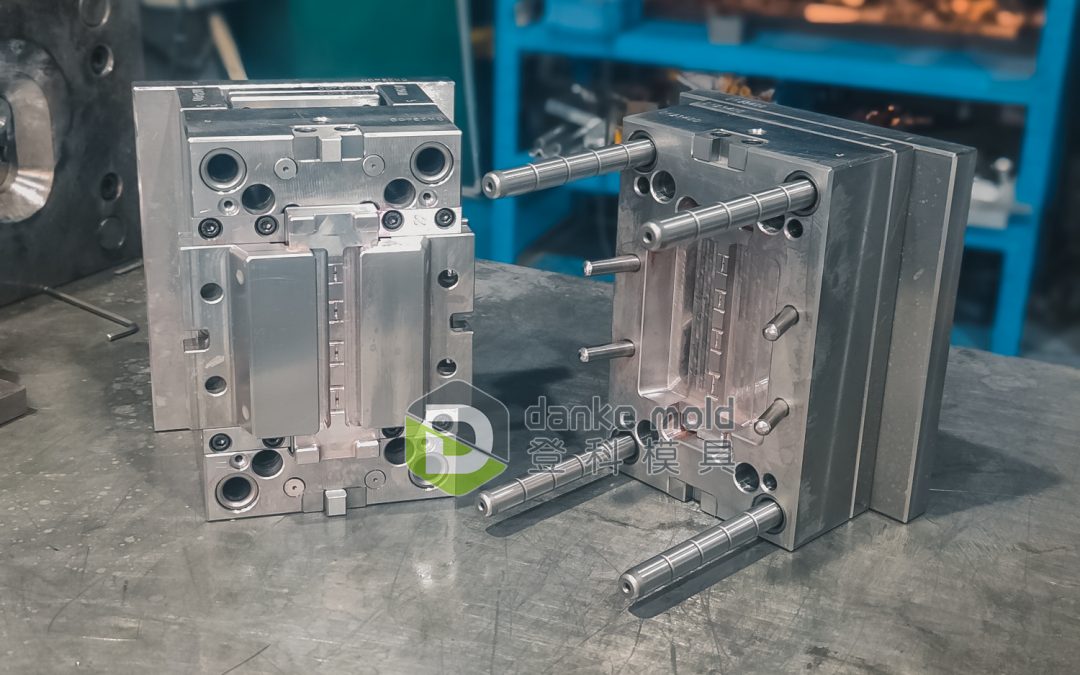

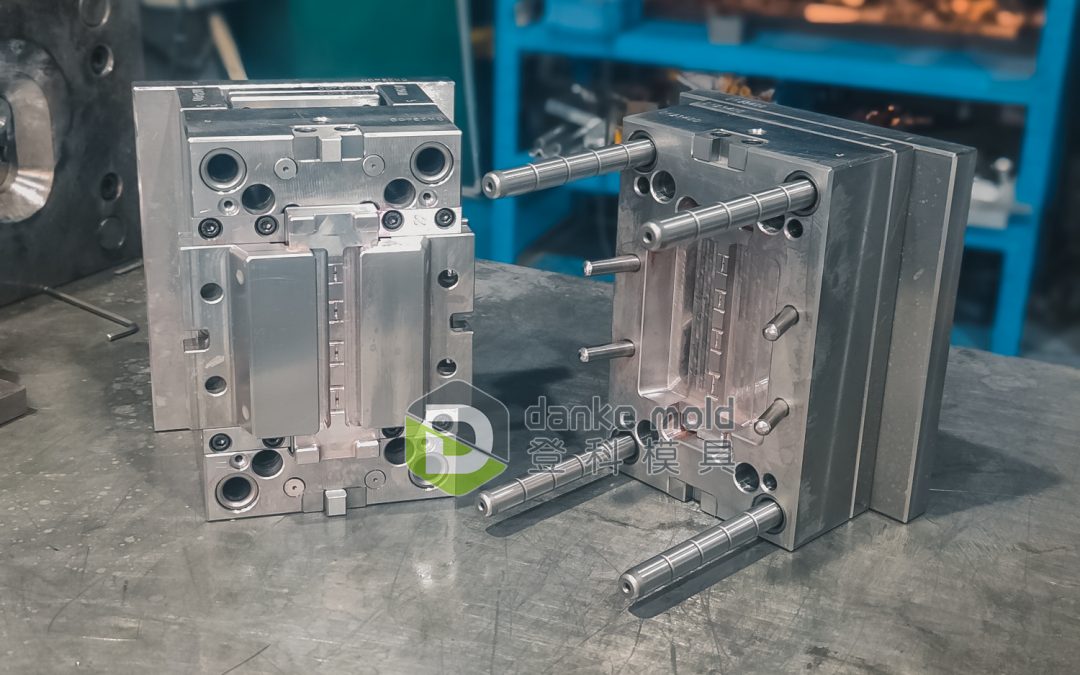

In plastic injection molding project manufacturing processes, after CNC machining, EDM/Wire cutting, surface polishing, mold assembly would be the last but not least key procedure that affects the injection mold quality. We hereby would like to present the assembly...

by Danke Mold | Feb 11, 2023 | Blog, Industry information, Rapid tooling & Injection molding

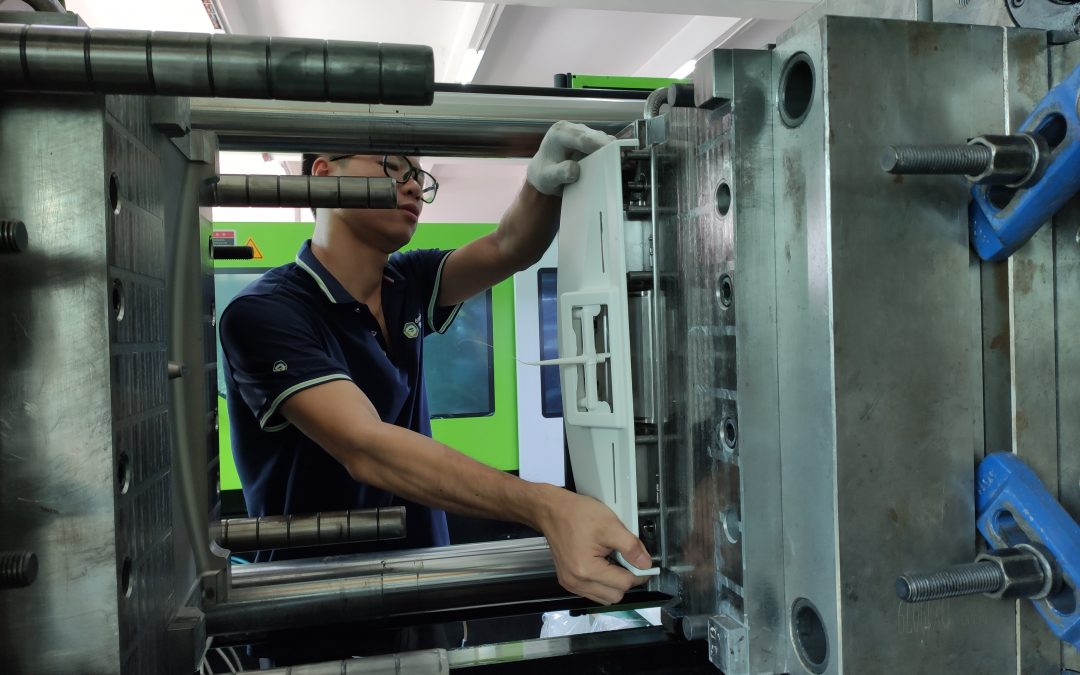

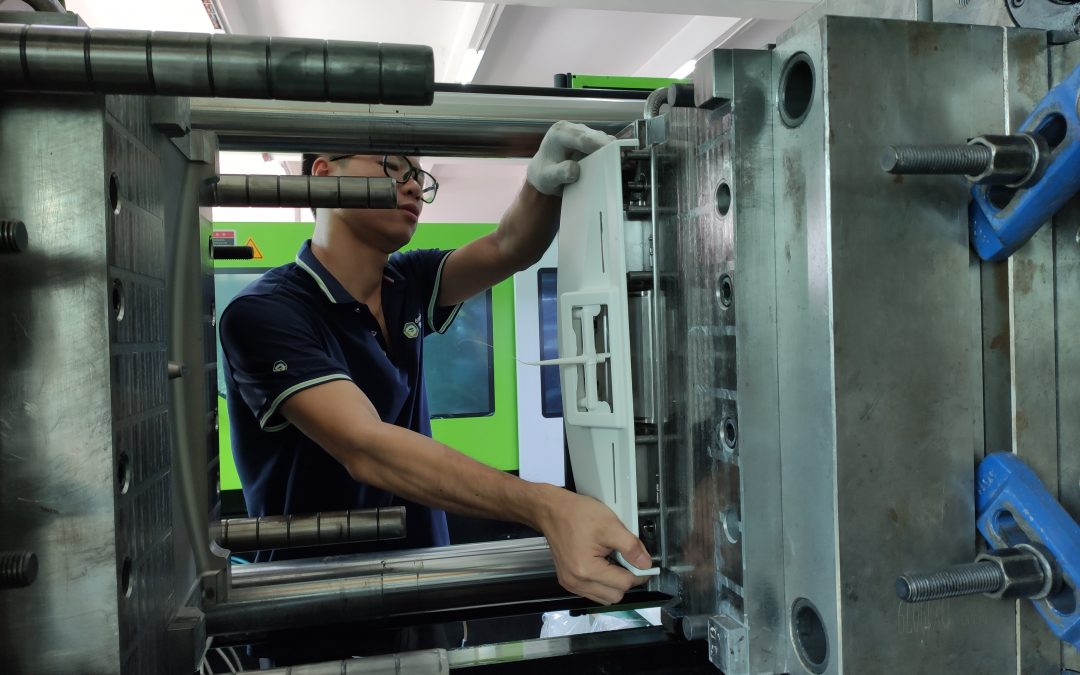

The quality control is essential and important in plastic injection molding. The injection molding is indeed one of the excellent options for the high volume production. If you are dealing with the plastic injection molding and looking to improve the quality of your...

by Danke Mold | Feb 7, 2023 | Blog, Industry information, Rapid tooling & Injection molding

The plastic injection molding is indeed one of the prominent techniques involved in providing you access to a highly fully fledged experience in terms of an excellent experiences in helping you enjoy a very decent product quality ever. But if you want to maintain the...

by Danke Mold | Feb 3, 2023 | Blog, Rapid tooling & Injection molding

The plastic injection molding has been growing quite consistently over the years. If you are looking to indulge in producing in large numbers, nothing can beat the experience with the plastic injection molding. Advantages of plastic injection molding Some of the...