by Danke Mold | Jan 11, 2019 | Blog

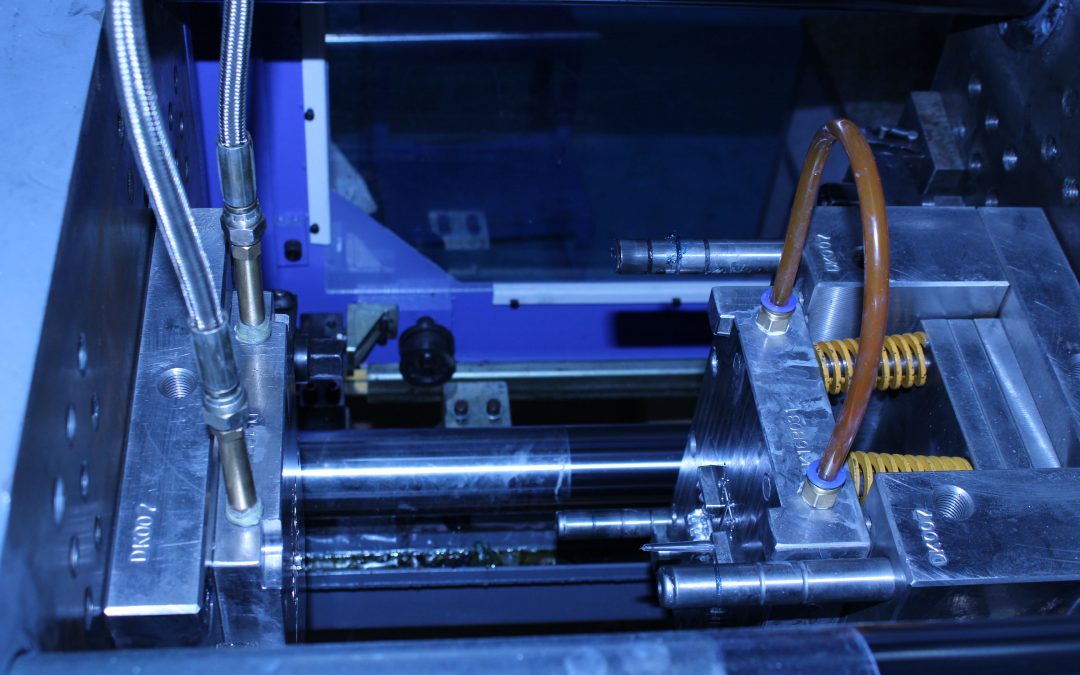

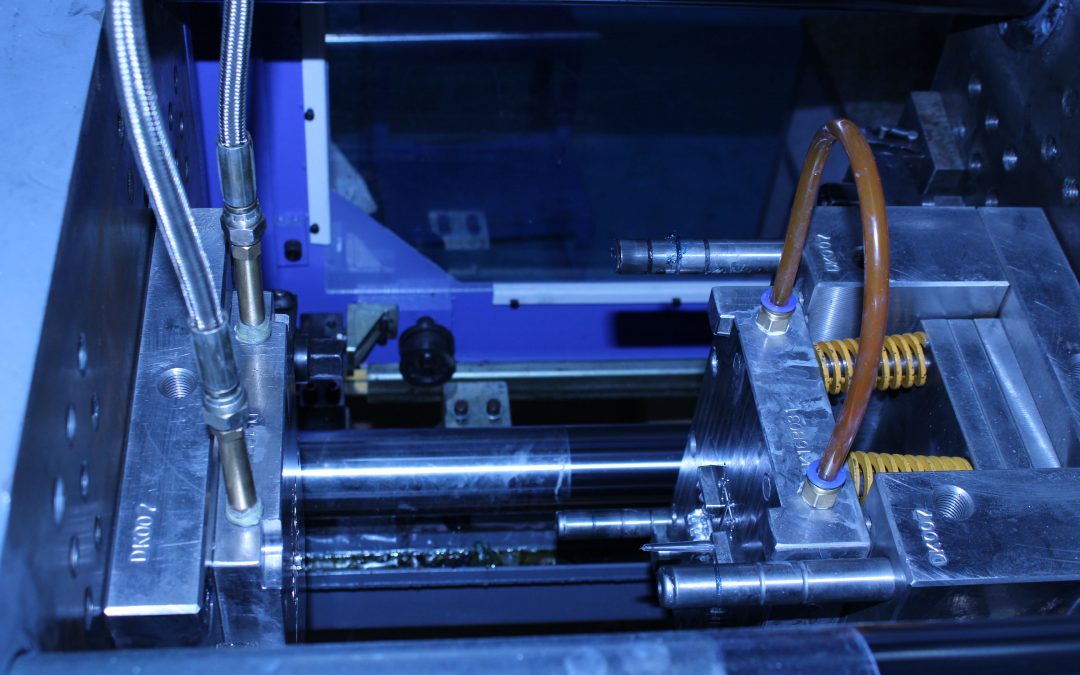

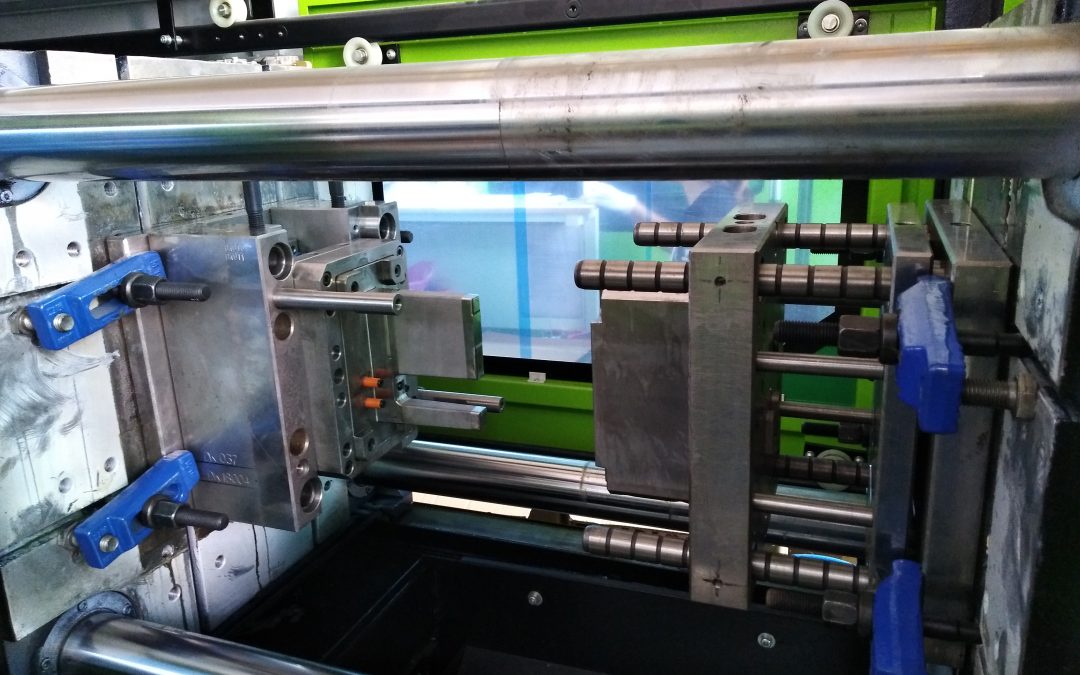

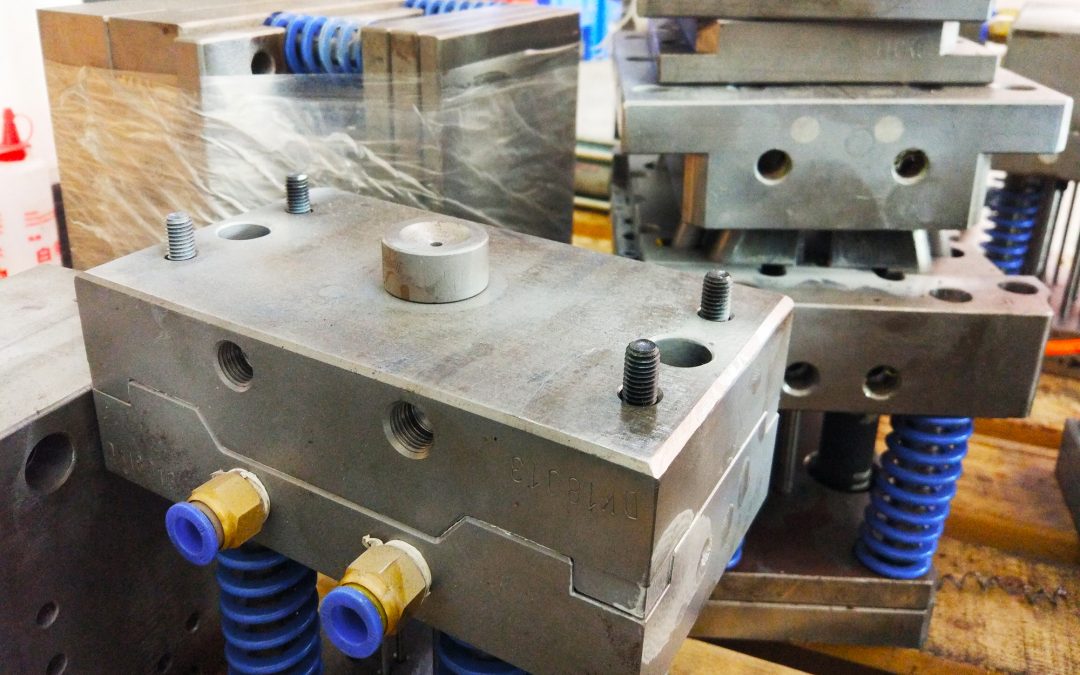

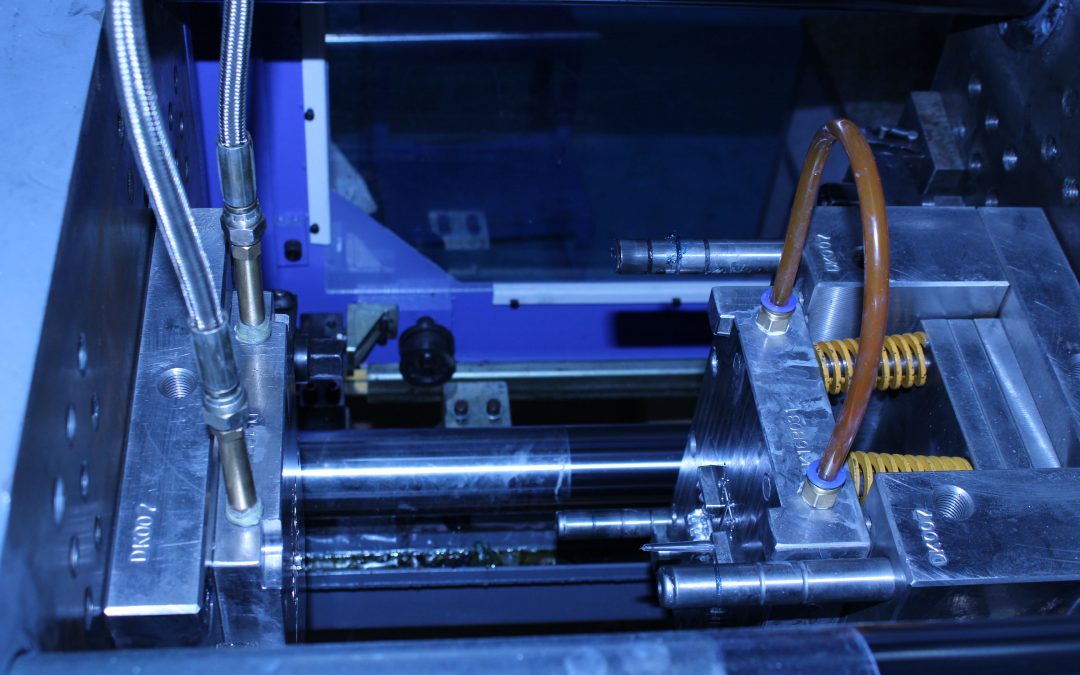

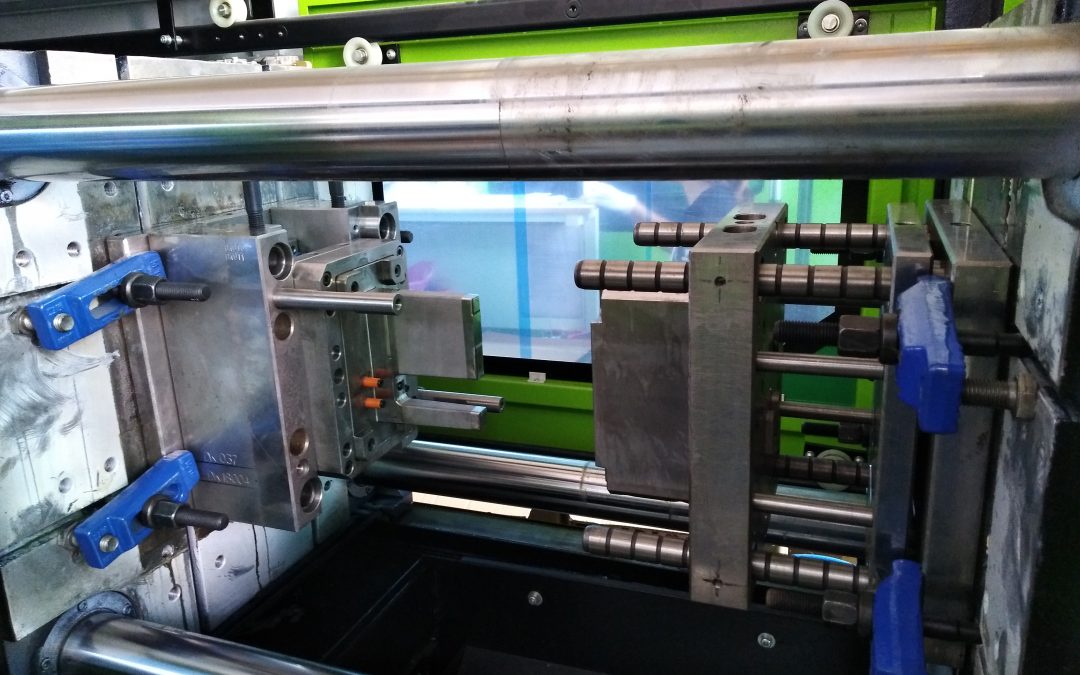

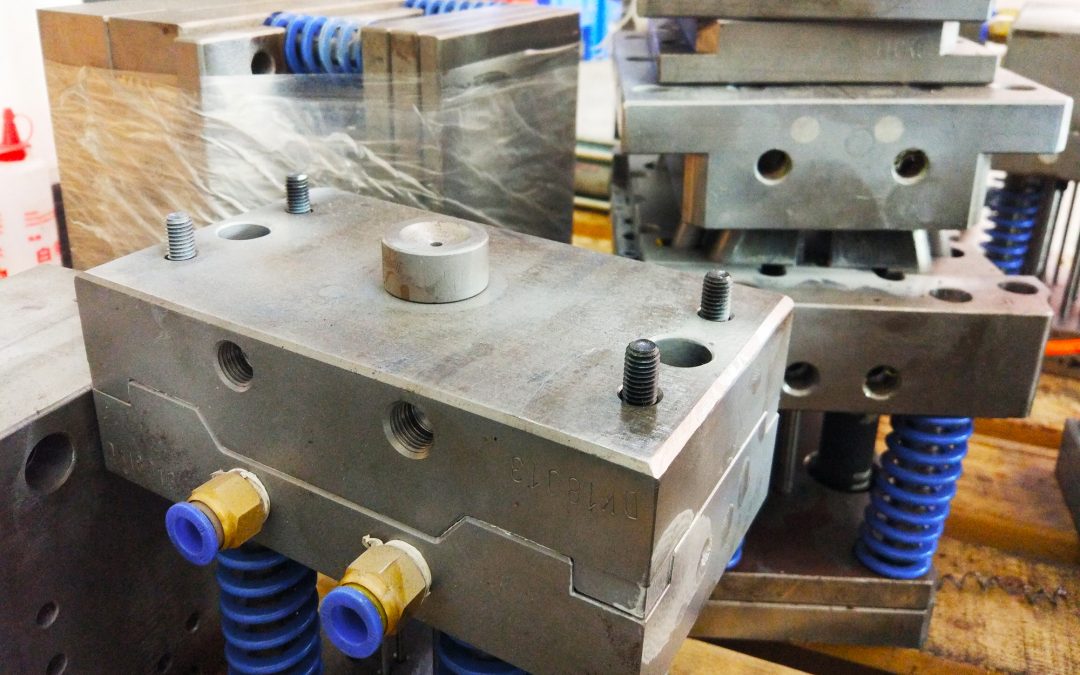

Rapid Tooling – some Injection Molding experiences Rapid Tooling is a simplified injection molding mold. A better understanding of injection molding, will be good for cost saving and shortening lead time. We organized some injection molding experiences,...

by Danke Mold | Jan 9, 2019 | Blog

What is Rapid Tooling? Pros, Cons and Applications When we talk about rapid tooling, normally we refer it to a fast-turn around injection molding tool, with a relative-low tooling cost comparing with a conventional injection mold. 2 main Pros of Rapid...

by Danke Mold | Dec 25, 2018 | Blog

4 Axis CNC machining for On-Demand manufacturing Besides rapid tooling and plastic injection molding, we also provide rapid prototyping and on-demand manufacturing services. Therefore, we usually receive some enquiries that include a various of...

by Danke Mold | Nov 27, 2018 | Blog

Recruitment Danke Mold provides these services: rapid plastic injection mold design and production, injection molding, CNC machining and 3D printing. Our clients are from all over the world, including USA, Canada, Germany, UK, the Netherlands. Talent is the...

by Danke Mold | Nov 7, 2018 | Blog

Material selection for rapid tooling production As a rapid mold maker & injection molding manufacturer, some questions are frequently asked by our clients, such as “What materials will be used in making my injection molds?”, “If we change the material into...