Access to clean water is often a major concern in disaster relief situations. The ability to quickly produce portable water storage solutions is essential for aiding communities in crisis. Blow molding, a highly efficient manufacturing process, is key in rapidly producing water containers that can be easily transported and used in emergencies. This article explores how blow molding supports disaster relief efforts, focusing on portable water storage, its benefits and challenges, and environmental considerations.

Introduction to Blow Molding in Disaster Relief

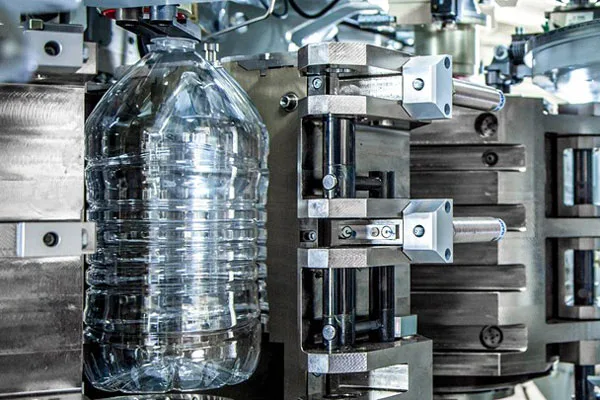

Blow molding is a manufacturing process used to create hollow plastic products, such as bottles and tanks, by inflating a heated plastic tube inside a mold. This method is particularly valuable in disaster relief because it produces large quantities of lightweight, durable containers at high speeds. In emergencies, blow molding enables the rapid production of portable water storage containers essential for storing clean water during recovery periods.

The Importance of Portable Water Storage

Access to clean water is often disrupted during natural disasters like floods, earthquakes, and hurricanes. Portable water storage solutions are critical for ensuring affected populations access drinking water, sanitation, and cooking resources. Blow molding allows for the quick production of lightweight containers that can be easily distributed in disaster zones. These containers are designed for easy transport, filling, and storage, ensuring that clean water can be safely collected and stored until more permanent infrastructure is restored.

Portable water storage containers made through blow molding provide flexibility in disaster relief efforts. They can store water from emergency sources and are essential in maintaining public health while long-term water systems are being repaired or rebuilt.

Large PET bottles

Benefits and Challenges of Blow Molding for Rapid Production

Benefits

- Speed and Efficiency: Blow molding allows for rapidly producing large volumes of water storage containers. In disaster relief, this speed is crucial for meeting immediate needs in the affected areas.

- Cost-Effective: Blow molding is a cost-efficient process that helps keep production costs low. This makes it an affordable option for relief organizations that need to maximize their budgets in disaster situations.

- Durability: The materials used in blow molding, such as high-density polyethylene (HDPE), offer durability and resistance to impact. This ensures that water containers can withstand harsh handling in disaster environments.

Challenges

- Material Constraints: The plastic used in blow molding may not be ideal for long-term storage, as it can degrade with UV exposure or chemical contamination.

- Logistical Barriers: Manufacturing facilities capable of blow molding may not be immediately available in disaster zones, leading to potential production delays if the supply chain is not properly coordinated.

Environmental Considerations in Blow Molding Production

Although blow molding offers numerous advantages, there are environmental concerns related to plastic waste. Non-biodegradable plastics can contribute to environmental pollution once the containers are no longer needed.

To address this, it is important to use recyclable plastics in blow molding production. Many manufacturers are now exploring using post-consumer recycled plastic to reduce the environmental impact. Promoting reuse and recycling of containers after use can further minimize waste.

Conclusion

Blow molding plays a vital role in disaster relief, enabling the quick production of portable water storage solutions. Blow molding ensures that clean water is available after natural disasters by offering durable and cost-effective containers. However, addressing plastic production’s environmental impact and prioritizing sustainability is essential. With ongoing innovation, blow molding can continue to support disaster relief efforts while minimizing environmental harm.