by Danke Mold | Apr 11, 2025 | Plastic Injection Molding

Plastic injection molding plays a crucial role in producing disposable medical supplies. This efficient manufacturing process allows for the rapid, high-volume production of essential items like syringes, surgical instruments, and PPE. As healthcare demands continue...

by Danke Mold | Mar 18, 2025 | Plastic Injection Molding

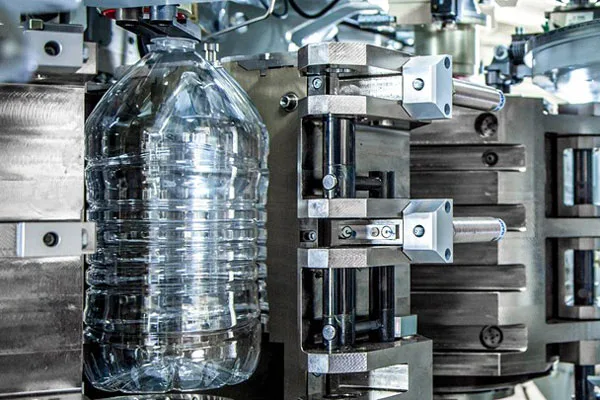

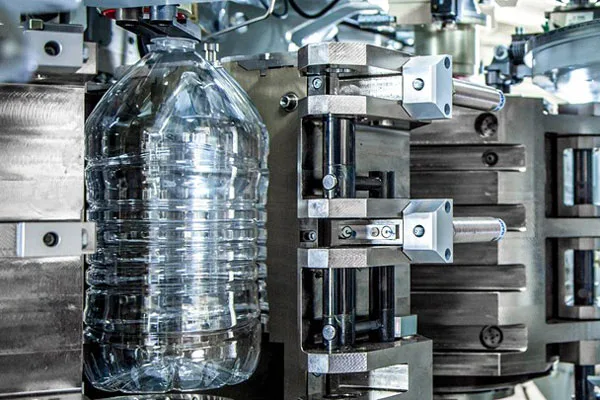

Access to clean water is often a major concern in disaster relief situations. The ability to quickly produce portable water storage solutions is essential for aiding communities in crisis. Blow molding, a highly efficient manufacturing process, is key in rapidly...

by Danke Mold | Mar 15, 2025 | Plastic Injection Molding

Artificial intelligence (AI) is revolutionizing plastic injection molding, bringing unprecedented precision, efficiency, and automation to smart factories. Manufacturers are redefining how plastic components are produced by leveraging AI-driven optimization,...

by Danke Mold | Mar 12, 2025 | Plastic Injection Molding

In the age of Industry 4.0, manufacturers are rewriting the rules of production. By fusing plastic injection molding with artificial intelligence (AI), companies are revolutionizing product production and achieving unprecedented efficiency, accuracy, and...

by Danke Mold | Mar 8, 2025 | Plastic Injection Molding

Injection molding, a cornerstone of modern manufacturing, is a complex process with numerous variables influencing its success. Each step presents unique challenges, from material selection and mold design to process parameters and quality control. The intricate...

by Danke Mold | Feb 18, 2025 | Plastic Injection Molding

2-shot or dual-material injection molding, also known as 2K injection molding, is a novel manufacturing method that uses two materials in one molding cycle to make products with unique features. This method is common across sectors because it produces functional,...