by Danke Mold | Feb 7, 2025 | Plastic Injection Molding

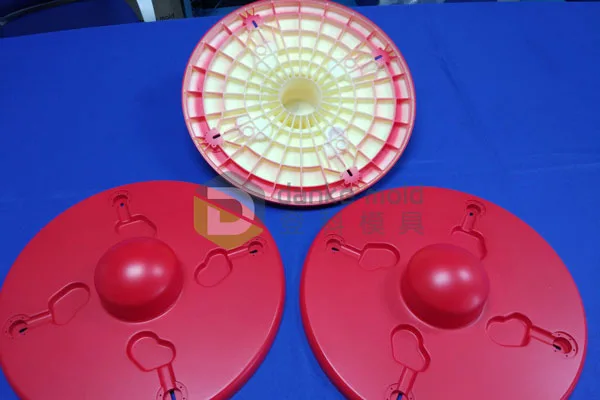

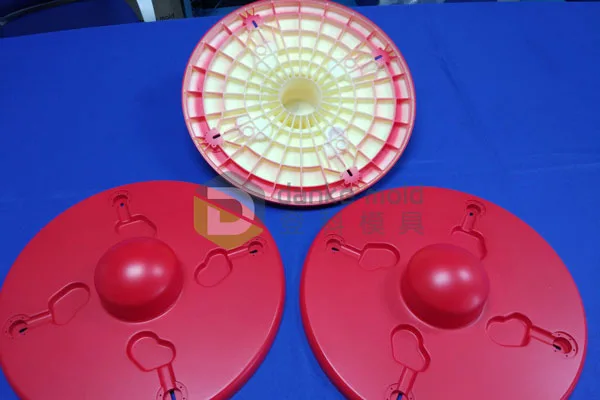

The unique two-shot injection molding (2K) process makes plastic parts from two materials in one cycle. This technique is used to make high-performance components that need flexible, durable, or beautiful materials. From cars to consumer items, 2K injection molding is...

by Danke Mold | Feb 3, 2025 | Plastic Injection Molding

The unique two-shot injection molding (2K) process makes plastic parts from two materials in one cycle. This technique is used to make high-performance components that need flexible, durable, or beautiful materials. From cars to consumer items, 2K injection molding is...

by Danke Mold | Jan 27, 2025 | Plastic Injection Molding

2K injection molding, commonly known as two-shot or dual-material injection molding, is an innovative manufacturing technology that creates components from two materials in one cycle. This method is flexible and may generate parts with softness, durability, and color....

by Danke Mold | Jan 23, 2025 | Plastic Injection Molding, Uncategorized

Plastic injection molding makes plastic components correctly, efficiently, and cheaply in modern manufacturing. This article examines plastic injection molding uses, advantages, and advances. Know Plastic Injection Molding Melten plastic is injected into a mold to...

by Danke Mold | Dec 24, 2024 | Plastic Injection Molding

Injection molding makes complex, precise, and durable plastic products. It makes several high-quality, low-waste goods for medical gadgets and vehicle parts. The method, merits, problems, and future of plastic injection molding are addressed here. Plastic Injection...

by Danke Mold | Dec 17, 2024 | Plastic Injection Molding

Mass-producing accurate and sophisticated plastic products requires injection molding. This technique is vital for modern production, from consumer goods to car parts. This page covers plastic injection molding’s benefits, applications, and advancements. Plastic...