by Danke Mold | Feb 14, 2023 | Blog, Industry information, Rapid tooling & Injection molding

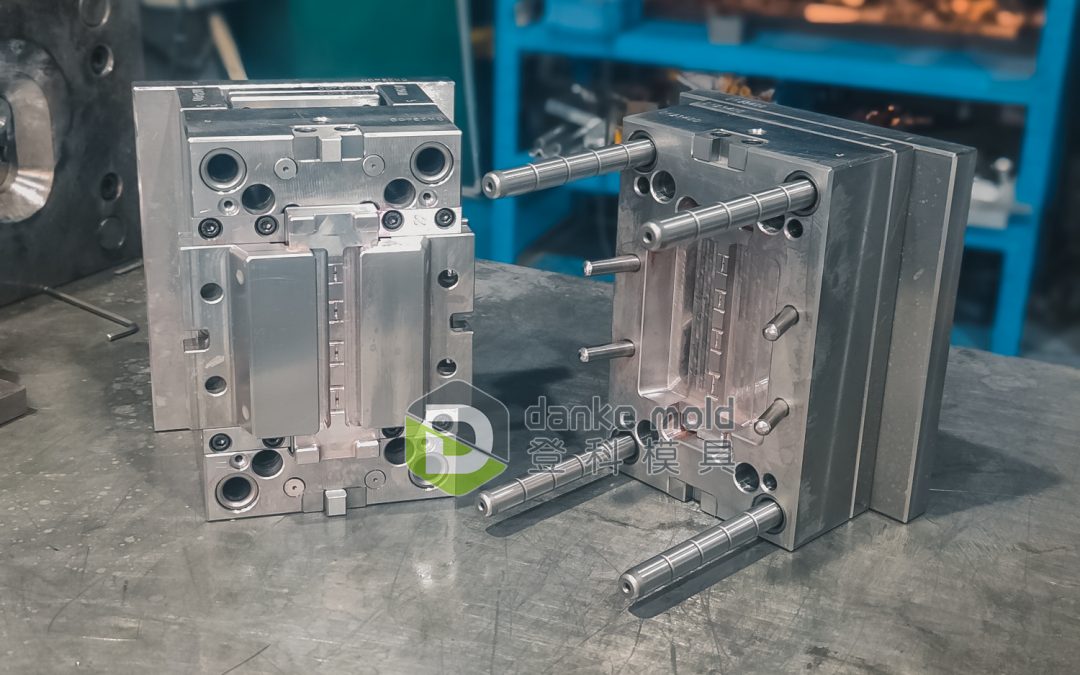

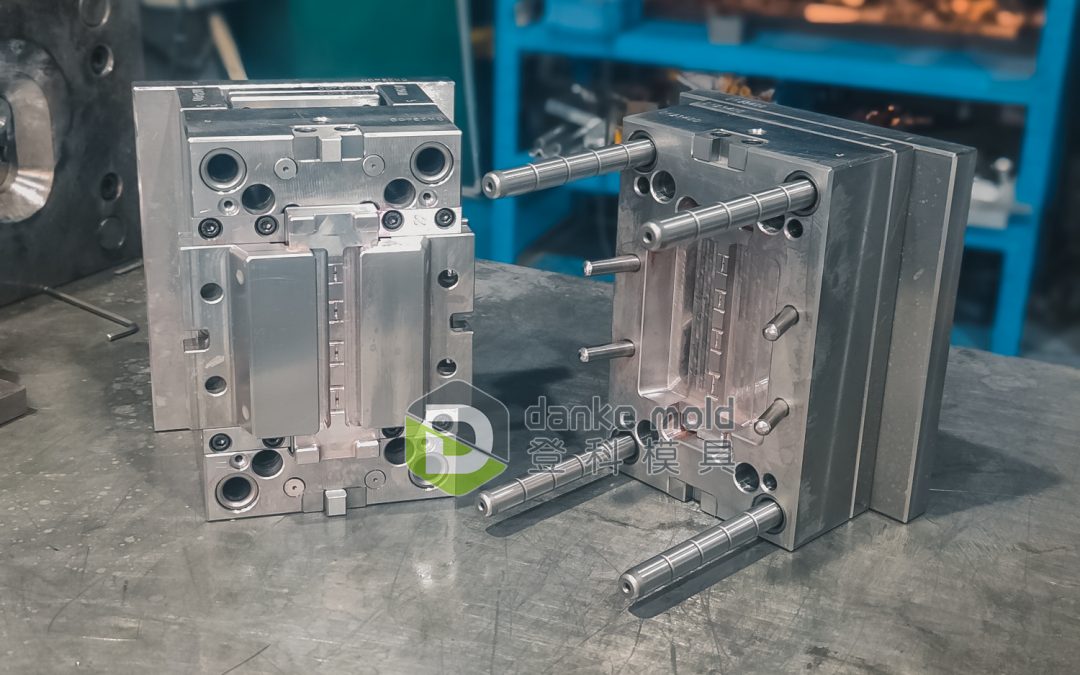

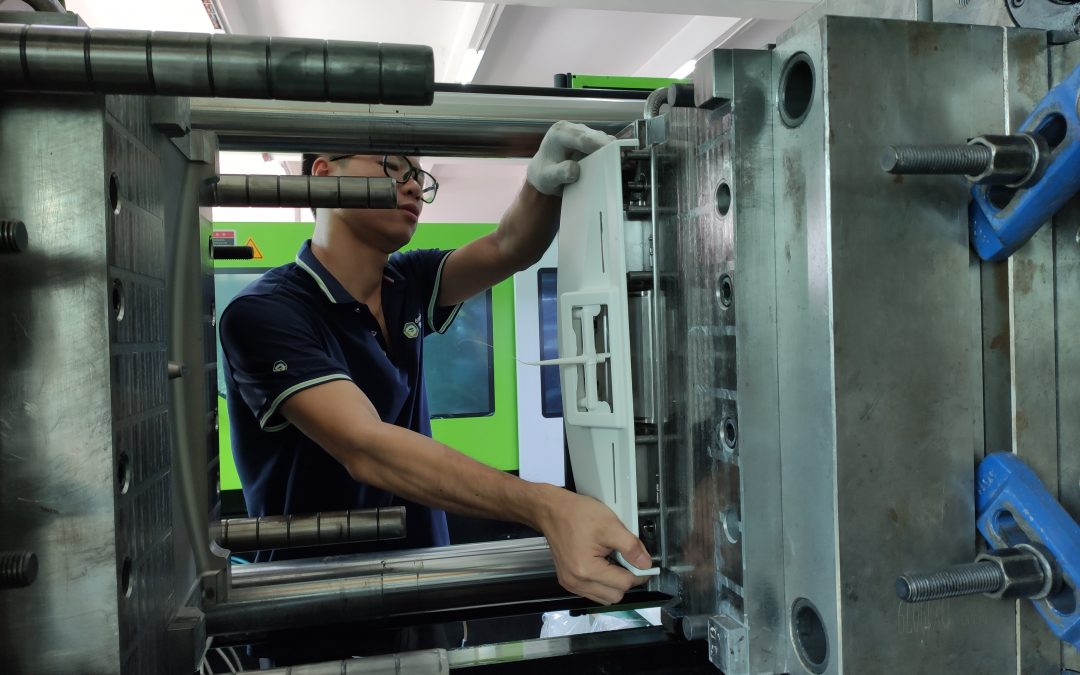

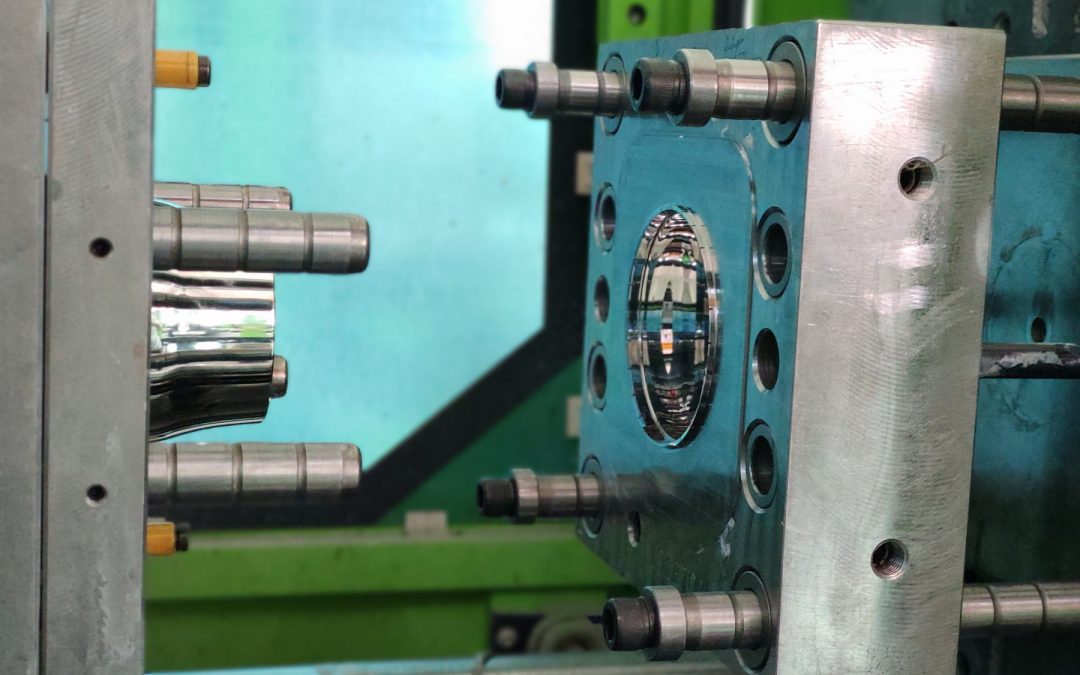

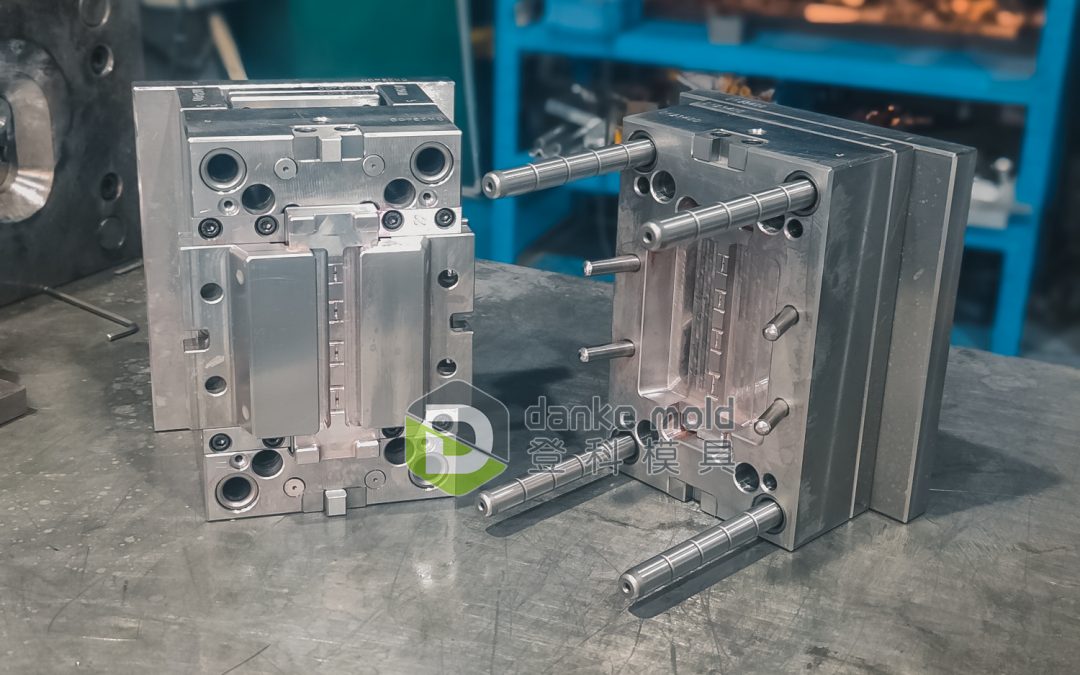

In plastic injection molding project manufacturing processes, after CNC machining, EDM/Wire cutting, surface polishing, mold assembly would be the last but not least key procedure that affects the injection mold quality. We hereby would like to present the assembly...

by Danke Mold | Feb 11, 2023 | Blog, Industry information, Rapid tooling & Injection molding

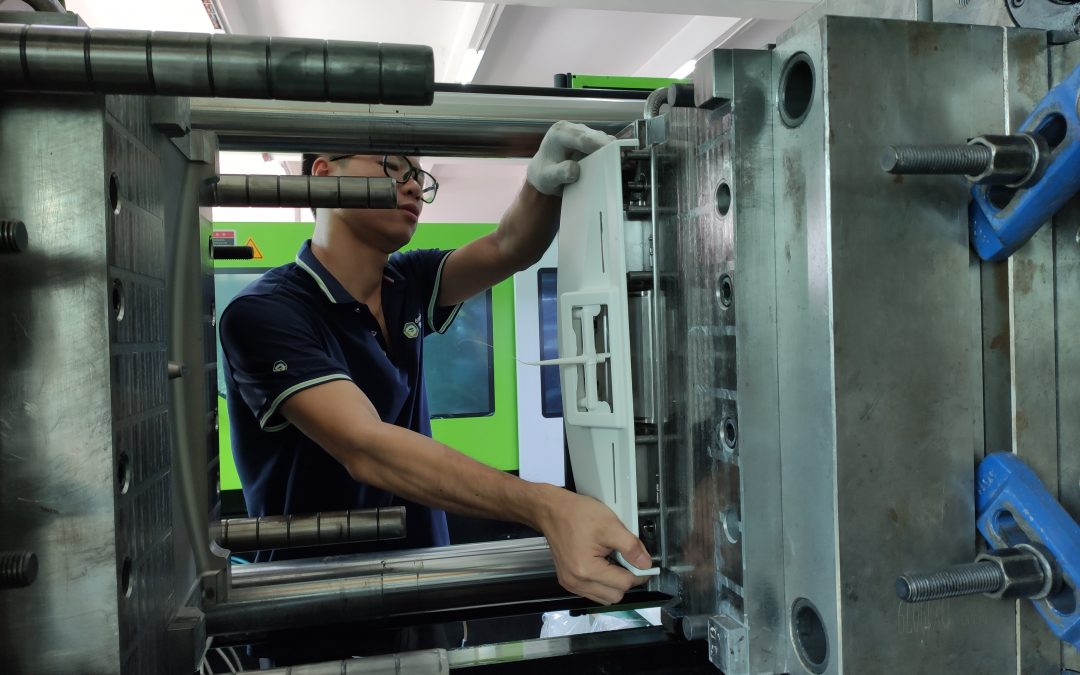

The quality control is essential and important in plastic injection molding. The injection molding is indeed one of the excellent options for the high volume production. If you are dealing with the plastic injection molding and looking to improve the quality of your...

by Danke Mold | Feb 7, 2023 | Blog, Industry information, Rapid tooling & Injection molding

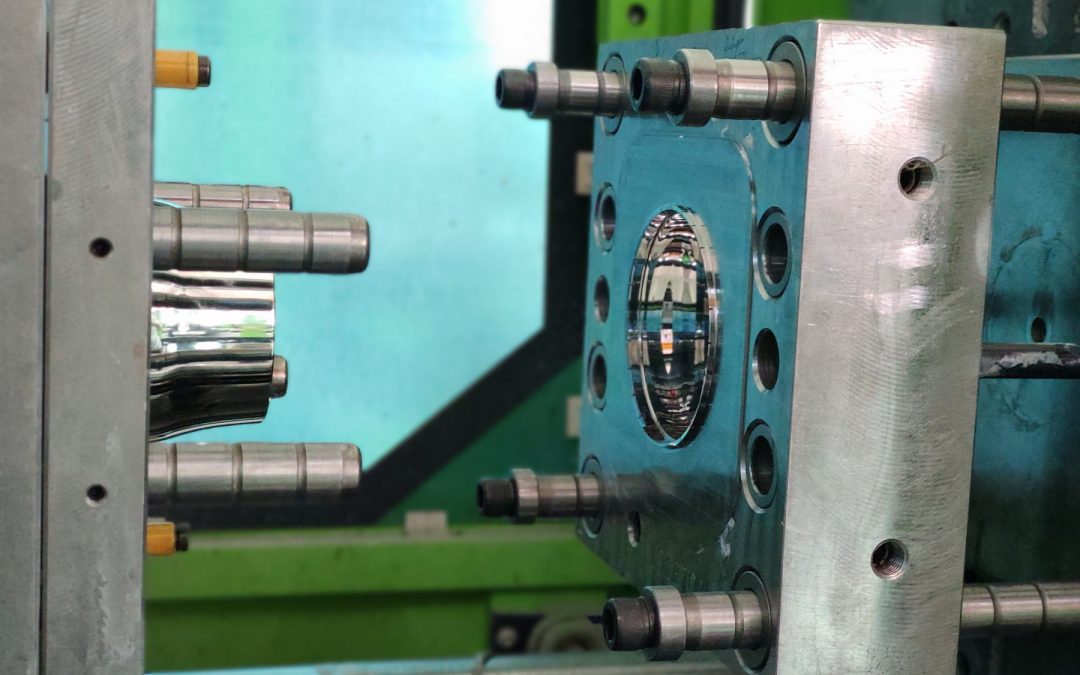

The plastic injection molding is indeed one of the prominent techniques involved in providing you access to a highly fully fledged experience in terms of an excellent experiences in helping you enjoy a very decent product quality ever. But if you want to maintain the...

by Danke Mold | Feb 3, 2023 | Blog, Rapid tooling & Injection molding

The plastic injection molding has been growing quite consistently over the years. If you are looking to indulge in producing in large numbers, nothing can beat the experience with the plastic injection molding. Advantages of plastic injection molding Some of the...

by Danke Mold | Jan 30, 2023 | Blog, Industry information, Rapid tooling & Injection molding

When it comes to the plastic injection molding is concerned, you would find that there are several parameters that you would find much exciting and innovative. With the best in class high tech equipment and a superior quality of the end products, you would find that...

by Joe Deng | Jan 21, 2019 | Blog, Rapid tooling & Injection molding

How to have cost efficiency Injection Molding Prototypes We learned that there are a lot of advantages of using injection molding for prototype making. For example: Real part material as volume molding production; Real surface finish as volume molding...