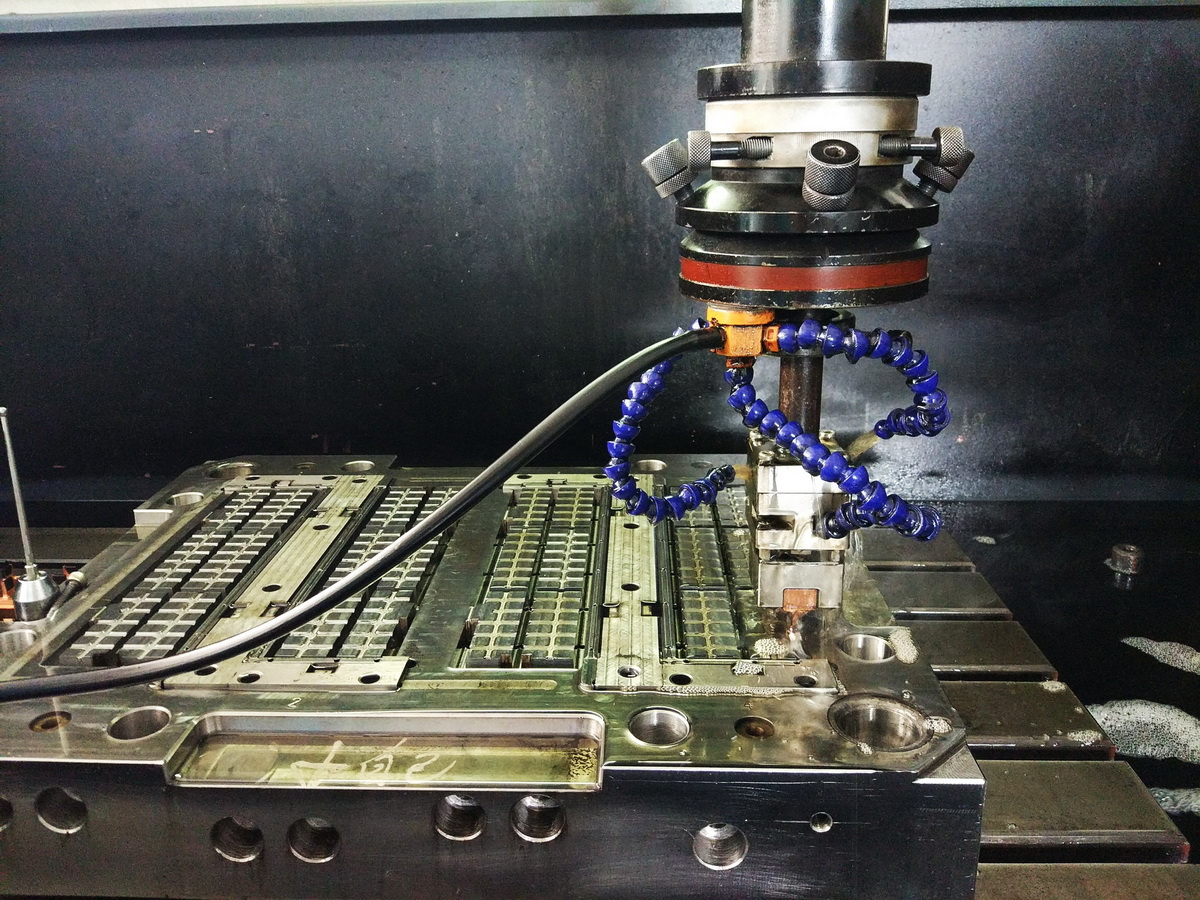

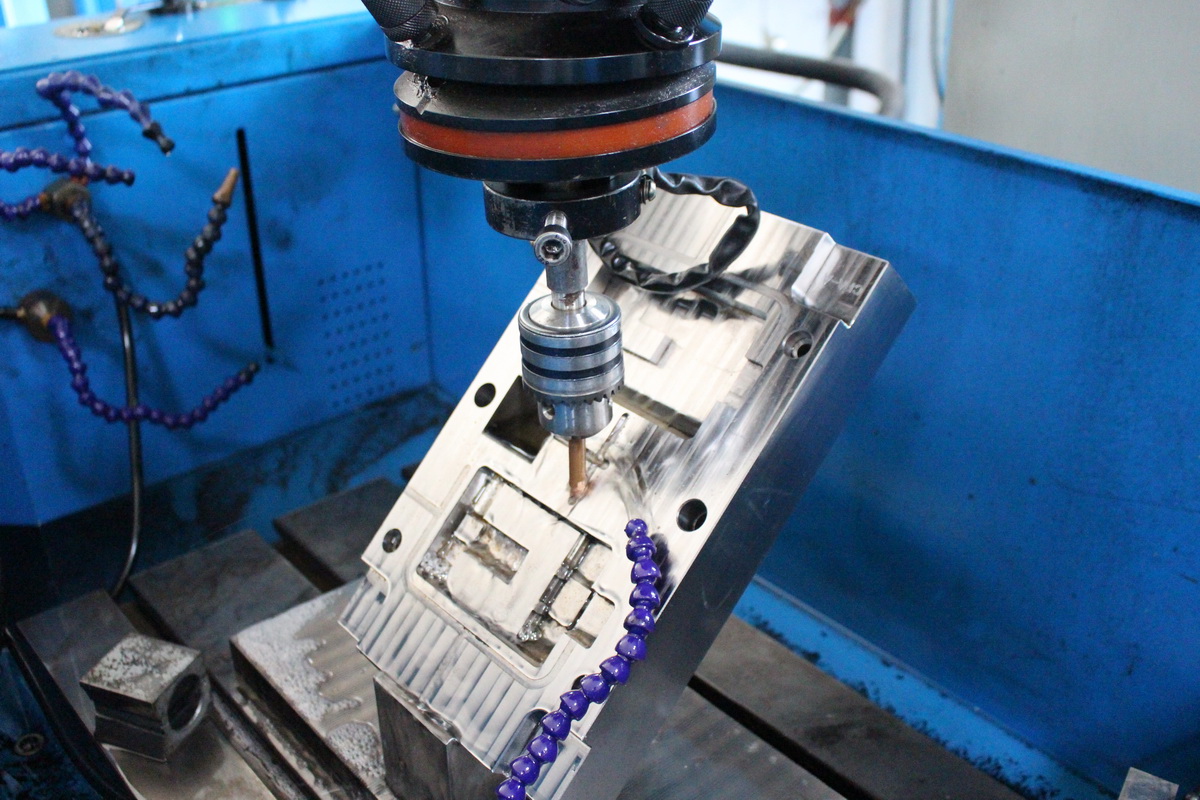

Electrical Discharge Machining (EDM) is a proven complementary method to traditional manufacturing processes like CNC milling and turning. When traditional machining methods reach their limit, electric discharge machining can be the solution. The EDM process allows for high accuracy and is applicable for any conductive material. and is well suited to producing components with complicated structure, In tool and mould making and some quick turn prototypes, EDM is very popular due to its applicability especially for hard materials like titanium or for particularly complex shapes that are hard to achieve with milling.

About the EDM process, it is a nontraditional precision machining process whereby a typically conductive material work piece has features created by the controlled erosion of material using electrical discharges .

At its core, it involves the direction of high-frequency electrical spark discharges from a graphite or soft metal tool, which serves as an electrode, to disintegrate electrically conductive materials such as hardened steel or carbide.

The current flow between electrodes is not constant; rather it is instantaneous, producing debris which is flushed out by the fluid. This can be done repeatedly to erode a finely controlled feature that would be impossible to create utilizing traditional machining methods.

Typically, the electrodes for die sinking EDM are made of copper or graphite. The main factors that influence the decision for an electrode material are the electrode’s conductivity and its resistance to erosion. Graphite has the advantage that it is easier to machine than copper. However, copper is highly conductive and strong. Brass, an alloy of cupper and zink, is often used for wire EDM or small tubular electrodes.

Advantages of Electrical Discharge Machining

- Machining of complex shapes that would otherwise be difficult to produce with conventional cutting tools

- Machine features to accuracy tolerances for high precision mechanical components

- Allows users to machine hardened workpieces.

- Lack of mechanical force put into the workpiece. Fragile outlines are easier to produce because there is no high cutting force needed to remove the material.

- Little or no polishing is required after the process is complete

Disadvantages of Electrical Discharge Machining

- The slow rate of material removal.

- The additional time and cost used for creating electrodes for Ram/Sink EDM.

- Reproducing sharp corners on the work piece is difficult due to electrode wear.

EDM is the mysterious black art of mold making, though nowadays it very technical and logical. Today’s EDM’s are truly amazing machine tools, without which modern mold making would not exist.

That’s EDM process. We will discuss some other key process for mold making.

Please click https://www.dankemold.com/ to get more information.