Danke Mold Blog

We would just like to share our rapid tooling, plastic injection molding and on-demand manufacturing ideas and experiences. Danke aims to provide you with a deeper understanding of the processes, best practices, and innovative approaches that have shaped our work in these fields.

Why Plastic Injection Molding Is the Future of High-Volume Production

A versatile and widespread plastic production process is injection molding. Modern manufacture, from household items to complicated vehicle components, uses this technology because to its economy, scalability, and adaptability. Plastic injection...

Mastering Plastic Injection Molding: From Concept to Mass Production

The speed, precision, and cost of plastic injection molding make it popular for component manufacturing. Auto, electronics, consumer, medical, and other industries use it. Pumping molten plastic into a mold hardens it. We cover plastic injection...

Plastic Injection Molding: The Backbone of Modern Manufacturing

Over molding produces simple and complicated items. This inexpensive method revolutionized mass production of high-quality, homogeneous components. We'll discuss over molding's various applications. Over molding Molten plastic is injected into a...

Rapid Tooling: Revolutionizing Manufacturing with Speed and Efficiency

Project success in the ever-changing industrial business requires time and precision. Rapid tooling (RT) revolutionizes prototype-to-production. By swiftly making molds, dies, and other equipment, rapid tooling accelerates product development. The...

What are the Types of Plastic Injection Molds?

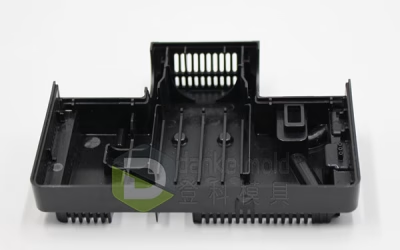

Let's take a closer look at injection mold tooling before we get started. Plastic injection molds are used to facilitate plastic injection molding. Custom mold tooling can be made from steel or aluminium to achieve desired results. They frequently...

Plastic Injection Molding Trends: Present and Future

The injection molding industry is going through major changes as we welcome the possibilities of 2024. These changes are being driven by global market dynamics, sustainability demands, and technological advancements. We'll analyse major trends and...

Vast Benefits of Injection Molding in Plastic

The benefits of injection molding are numerous. It is a highly repeatable method of precisely producing plastic or elastomeric parts while minimising molding costs. Once configured, it can have parts per hour using a variety of plastics and...

Methods for Choosing the Right Plastic Injection Molding

Almost every consumer product on the market or every industry uses plastic in one way or another. Electronics, consumer products, automotive, healthcare, and even aerospace all use plastic materials to make countless components with a wide range of...

Exploring the Versatility of Vacuum Casting for Low-Volume Production

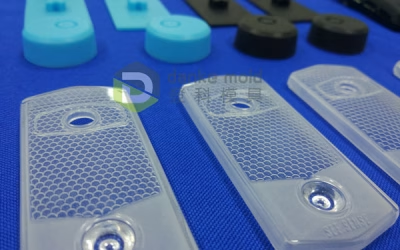

In the fast-paced world of product development, where time-to-market is critical, rapid prototyping has emerged as an essential tool for bringing ideas to life. Among the various prototyping methods available, vacuum casting stands out for its...

CNC Machining for Sustainable Manufacturing

CNC machining, a computer-controlled manufacturing process, is a marvel of versatility and efficiency. It uses cutting tools to craft precise and complex parts from a variety of materials, making it a cornerstone in industries such as aerospace,...

Injection Molding Beyond Plastics: Exploring New Frontiers in Material Possibilities

Injection molding has long been synonymous with the mass production of plastic parts. However, recent advancements have pushed the boundaries of this versatile manufacturing process, enabling a wider range of materials, from bioplastics and metals...

Vacuum Casting for Hyper-Realistic Prototyping

In rapid prototyping, where speed and precision intersect, vacuum casting stands out as a technique that can replicate intricate details and surface finishes with unparalleled accuracy. This process has become the go-to choice for designers and...