Danke Mold Blog

We would just like to share our rapid tooling, plastic injection molding and on-demand manufacturing ideas and experiences. Danke aims to provide you with a deeper understanding of the processes, best practices, and innovative approaches that have shaped our work in these fields.

Injection Molding Beyond Plastics: Exploring New Frontiers in Material Possibilities

Injection molding has long been synonymous with the mass production of plastic parts. However, recent advancements have pushed the boundaries of this versatile manufacturing process, enabling a wider range of materials, from bioplastics and metals...

Vacuum Casting for Hyper-Realistic Prototyping

In rapid prototyping, where speed and precision intersect, vacuum casting stands out as a technique that can replicate intricate details and surface finishes with unparalleled accuracy. This process has become the go-to choice for designers and...

Unveiling the Hidden Potential of Vacuum Casting in Production

Vacuum casting is often hailed as a champion of prototyping, enabling designers and engineers to quickly and cost-effectively create realistic models of their product concepts. However, this versatile manufacturing process offers much more than...

How CNC Machining Is Transforming Modern Manufacturing

Few technologies like Computer Numerical Control (CNC) machining have sparked a revolution in manufacturing. At its core, CNC machining involves using computer-controlled tools to make precise cuts and shapes in various materials. Gone are the days...

Vacuum Casting vs. Injection Molding: Choosing the Right Process for Your Project

The choice of the right manufacturing process is pivotal to bringing your product vision to life. Whether you're developing a prototype or gearing up for mass production, deciding between vacuum casting and injection molding for plastic parts can...

Vacuum Casting: A Precision Manufacturing Technique

Vacuum casting, a unique manufacturing technology, is used for high-quality prototypes and limited production runs that may be manufactured with unsurpassed precision and complexity. Nowadays, industries seeking quick and effective manufacturing...

Design for Injection Molding: Your Blueprint for Successful Plastic Parts

In the world of plastic part manufacturing, injection molding reigns supreme. It's a versatile and efficient process, but its success hinges on one crucial factor: good design. A well-designed part can mean the difference between a flawless...

Extending the Life of Your Injection Mold with Best Practices for Care and Maintenance

Your injection mold is a powerhouse of productivity, a precision tool engineered to churn out thousands, even millions, of flawless parts. This vital asset represents a significant investment for your business, but its value extends beyond its...

Is Outsourcing or In-House Injection Molding the Right Fit for Your Business?

Injection molding is a cornerstone of modern manufacturing, enabling the creation of intricate plastic parts for countless products. However, a critical decision looms for businesses venturing into this realm: should you handle injection molding...

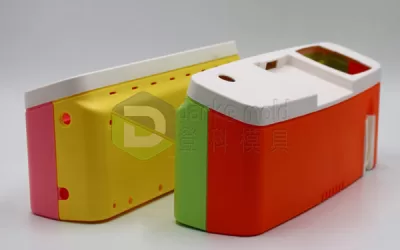

Basics of Plastic Injection Molding

A popular manufacturing technique is plastic injection molding, which involves melting tiny plastic pellets and shaping them into a variety of intricate pieces in big numbers. The production of items we use on a daily basis, such as phone casings,...

How Does a Plastic Injection Molding Function?

In order to reinforce, improve, and develop a broad variety of goods, plastic components are essential in various industries, including the automotive, home appliance, and medical device sectors. Since injection molding produces high-quality,...

The Future of Sustainable Manufacturing: Bioplastics and Injection Molding

Over 300 million tons of plastic are produced globally every year, with a significant portion ending up in landfills and oceans, wreaking havoc on ecosystems. As the devastating consequences of this plastic waste become increasingly apparent, the...