Danke Mold Blog

We would just like to share our rapid tooling, plastic injection molding and on-demand manufacturing ideas and experiences. Danke aims to provide you with a deeper understanding of the processes, best practices, and innovative approaches that have shaped our work in these fields.

Overmolding vs Insert Molding Comparison: Key Differences and Applications

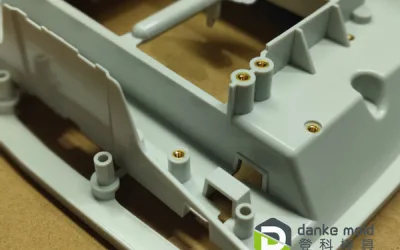

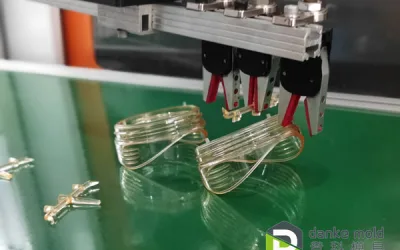

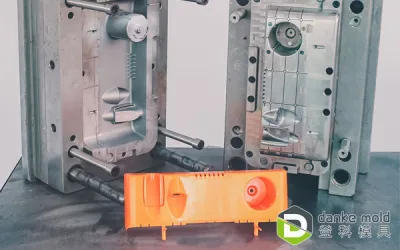

When choosing between overmolding and insert molding, understanding their key differences is crucial for ensuring the success of your project. Both are plastic injection molding techniques, but overmolding involves molding one material over another...

BMC Molding for Solar Inverters Enhances Durability and Efficiency

BMC molding plays a crucial role in the production of solar inverters by providing strong, heat-resistant, and lightweight components. You benefit from compression molding in BMC to create complex, durable parts that withstand thermal stress and...

The Rise of Low Volume Manufacturing: Why Small Batches Are Big Business

Low-volume manufacturing has transformed from a niche service into a dominant force shaping modern industry. Traditional mass production models give way to flexible manufacturing approaches serving specialized markets. Your business can capitalize...

The Hidden Costs of Volume Manufacturing (And How to Avoid Them)

Volume manufacturing appears straightforward on paper. You calculate material costs, labor expenses, and overhead. The final price seems reasonable. Yet many companies have discovered that their actual volume manufacturing costs far exceed initial...

Carbon Fiber Compression Molding Revival Driving Advanced Manufacturing Efficiency

Carbon fiber compression molding is experiencing a revival due to its cost-effective ability to produce strong, lightweight parts at scale. You can now achieve high-quality, durable components with faster production times compared to traditional...

Silicone Molding for Soft Robotics Enhancing Flexibility and Durability in Design

Silicone molding plays a crucial role in soft robotics, enabling the creation of flexible and durable components that mimic natural movements. This technique enables the production of complex shapes and smooth surfaces, which are essential for...

Maintaining Standards in High-Volume Manufacturing

The particular difficulties of high-volume manufacturing can determine the success of your product. Strategic planning and methodical execution are necessary to produce thousands or millions of units while maintaining constant quality. As...

High-Volume Manufacturing: Optimizing Production for Maximum Efficiency

Have you ever wondered how those smartphones, kitchen appliances, and automotive parts appear in endless supply with consistent quality? Welcome to the fascinating world of high-volume manufacturing—where creating thousands or even millions of...

Low-Volume Manufacturing: Flexibility and Precision for Specialized Production

In today's rapidly evolving product development landscape, low-volume manufacturing is crucial in specialized products, prototype development, and niche market applications. Amid supply chain disruptions and market uncertainties, low-volume...

Volume Manufacturing: Strategic Approaches for Efficient Production Scaling

Effective volume manufacturing capabilities determine a company's resilience and competitive edge in today's volatile global marketplace. With ongoing supply chain disruptions, labor shortages, and inflationary pressures affecting manufacturers...

Compression Molding: Achieving Precision with Thermoset Materials

Looking for parts that laugh in the face of extreme heat, provide bulletproof electrical insulation, or stay perfectly shaped under stress that would make other materials cry uncle? Compression molding might just be your manufacturing superhero!...

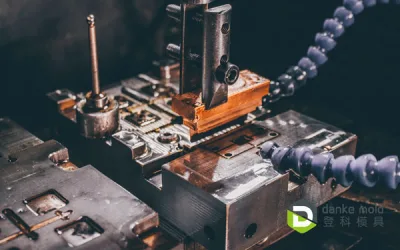

Understanding the Fundamentals of Plastic Injection Molding

Ever picked up your smartphone case and wondered, "How on earth did they make this?" You're holding the magic of plastic injection molding in your hands! This manufacturing superhero creates virtually everything from your kitchen gadgets to car...