In today’s lightning-fast business landscape, the speed at which you can bring a product to market can make or break your success. Delays can cost you valuable opportunities and leave you trailing behind competitors. Enter rapid tooling – a game-changing approach that can slash your development timelines and give you a decisive edge.

What is Rapid Tooling?

Rapid tooling is a collection of manufacturing techniques that allow you to create tooling (molds, dies, patterns) quickly and cost-effectively. Unlike traditional tooling methods, which can take weeks or even months, rapid tooling can often deliver results in days. This speed is a game-changer, especially when racing against the clock to launch a new product or iterate on an existing design.

The Technologies Behind Rapid Tooling

- 3D Printing: Also known as additive manufacturing, 3D printing builds objects layer by layer from digital designs. This technology is incredibly versatile, allowing for easy creation of complex geometries and intricate details.

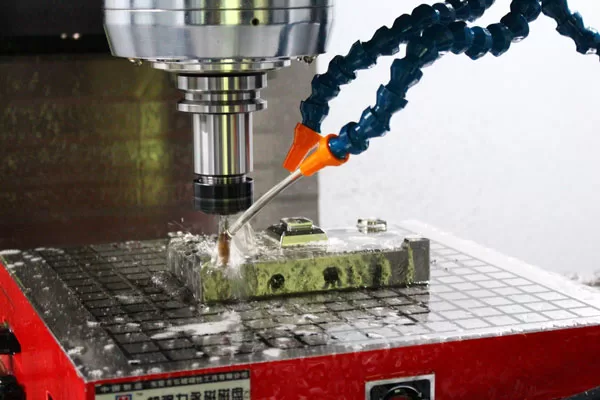

- CNC Machining: Computer Numerical Control (CNC) machining uses pre-programmed software to control tools that cut and shape materials. This method is known for its precision and ability to work with various materials, including metals and plastics.

- Other Technologies: Rapid tooling can involve casting, injection molding with aluminum tooling, and even traditional machining methods optimized for speed.

How Rapid Tooling Accelerates Product Development

- Faster Prototyping: Rapid tooling enables you to create functional prototypes in a fraction of the time compared to traditional methods. These prototypes can be used for testing, validation, and design refinement, accelerating development.

- Reduced Time to Market: Rapid tooling eliminates the lengthy lead times associated with traditional tooling, allowing you to launch your product sooner, capture market share, and generate revenue faster.

- Increased Design Flexibility: Rapid tooling technologies like 3D printing offer incredible design freedom, enabling you to iterate on designs quickly and easily. This flexibility is invaluable for fine-tuning your product before committing to expensive production tooling.

- Cost-Effective for Low-Volume Production: Rapid tooling is often more cost-effective than traditional methods for low-volume production runs. This makes it ideal for testing the market or producing limited-edition products.

- Bridge to Production: Rapid tooling can serve as a bridge to production by allowing you to create “bridge tooling” – molds or dies that can be used for limited production runs. At the same time, you finalize your design and invest in more durable production tooling.

CNC machines

Who Can Benefit from Rapid Tooling?

- Startups and Small Businesses: Rapid tooling is a democratizing force, leveling the playing field for smaller companies by giving them access to affordable and fast prototyping and manufacturing capabilities.

- Large Corporations: Even established companies can leverage rapid tooling to accelerate innovation, reduce development costs, and respond more quickly to changing market demands.

- Industries with Short Product Lifecycles: Industries like electronics, fashion, and consumer goods, where trends change rapidly, can greatly benefit from the speed and flexibility of rapid tooling.

Choosing the Right Rapid Tooling Partner

When selecting a rapid tooling partner, it’s essential to consider several key factors to ensure a successful collaboration and the best possible outcome for your project. Look for a company with a proven track record of delivering high-quality results on time and within budget. Experience in your industry or with similar products can be invaluable, as it demonstrates a deep understanding of the unique challenges and requirements you may face.

Expertise in the specific rapid tooling technologies you need is also crucial. Different projects may call for different approaches, such as 3D printing, CNC machining, or injection molding. A partner with a broad range of capabilities can offer more flexibility and tailored solutions to meet your specific needs.

Additionally, consider the partner’s communication style and willingness to collaborate closely with your team. A strong partnership built on open communication and mutual understanding can help ensure that your project stays on track and achieves its goals.

Finally, don’t forget to factor in the partner’s location and production capacity. A local partner may offer advantages in terms of logistics and ease of collaboration, while a partner with ample production capacity can ensure that your project is completed on time, even if it involves large volumes or tight deadlines.

The Future of Rapid Tooling

As technology advances, rapid tooling is only becoming faster, more affordable, and more accessible. This trend revolutionizes product development, enabling companies of all sizes to innovate at unprecedented speeds.

If you’re looking to accelerate your product development and gain a competitive edge, rapid tooling is the secret weapon you’ve been waiting for. Don’t let slow and outdated methods hold you back – embrace the future of manufacturing with rapid tooling.