by Danke Mold | Jul 21, 2018 | Blog

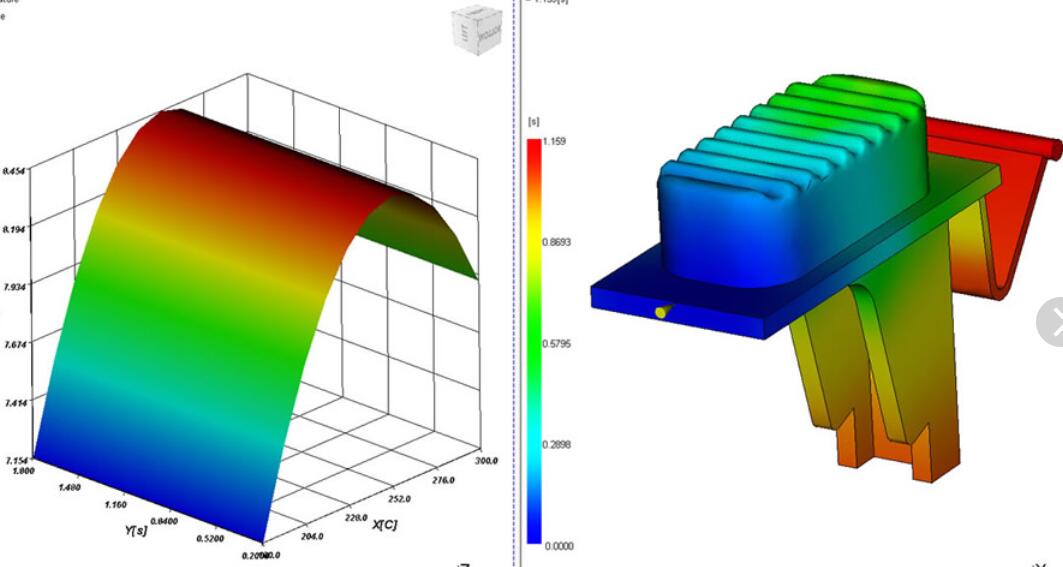

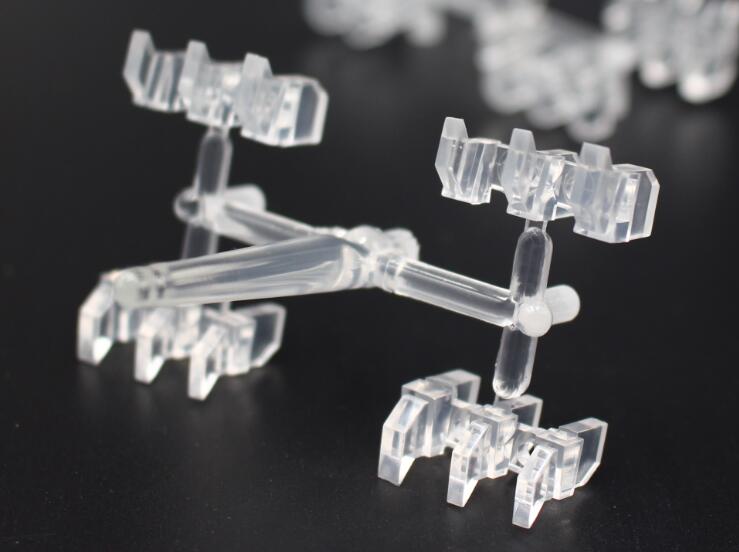

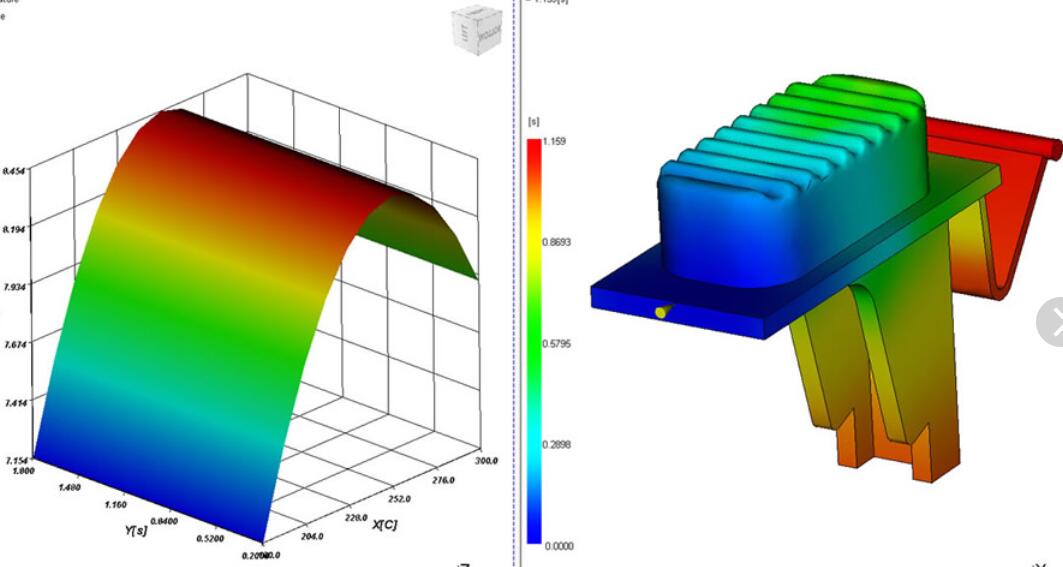

There are lots of injection mold manufacturers have Mold flow analyst, yet in order to save cost, they are usually not willing to do mold flow analysis unless the customer request. Actually, many big customers take mold flow analysis seriously for their products, but...

by Danke Mold | Jul 19, 2018 | Blog

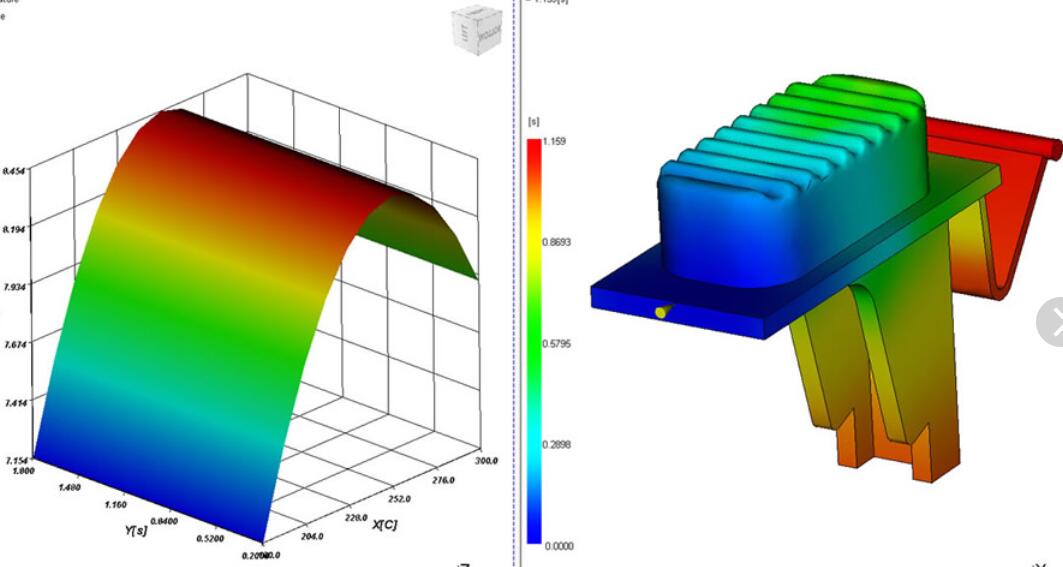

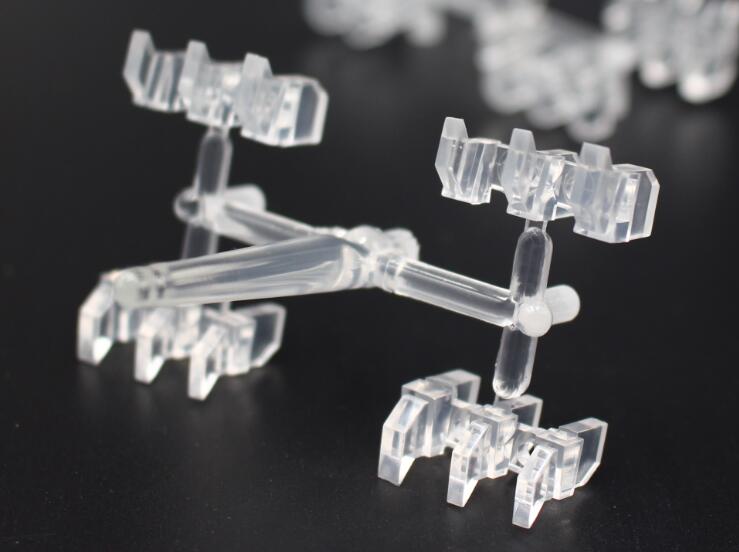

Along with higher quality and productivity requirements on plastic products, demand for injection molded parts continues to increase every year because plastic injection molding process is well known as the most efficient manufacturing techniques for producing of...

by Danke Mold | Jul 17, 2018 | Blog

Injection mold design is an important part of plastic product development. As a mold maker and injection molding factory, in order to improve the quality of parts, enhance tools performance and save manufacturing cost, we always keep thinking how to optimize the...

by Danke Mold | Jul 11, 2018 | Blog, Uncategorized

The last thing to be done in the injection mold making process is always the mold assembly. Last but not least. Mold assembly is always critical for tooling and molding quality. Suppose that, the cores and cavities are done perfectly, the mold base has been...

by Danke Mold | Jul 4, 2018 | Blog

Mold polishing is primarily a manual process requiring a high level of skill and knowledge. Mold polishing is perhaps the only operation that is not able to be automated, when all the CNC machining, EDM machining, surface grinding, and wire cutting are completed, the...