by Danke Mold | Jun 30, 2018 | Blog

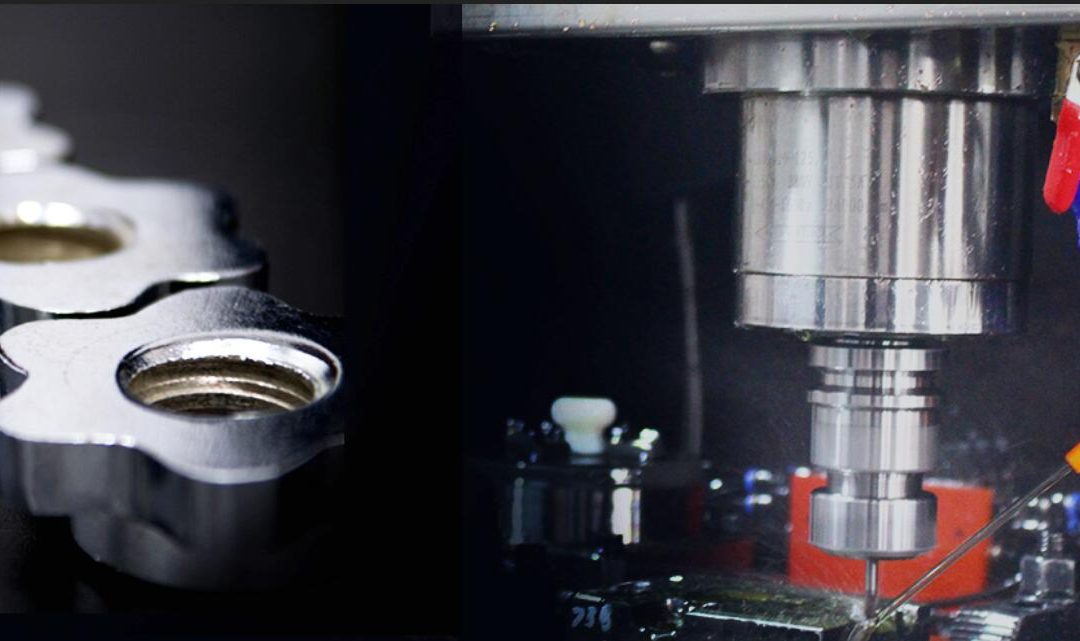

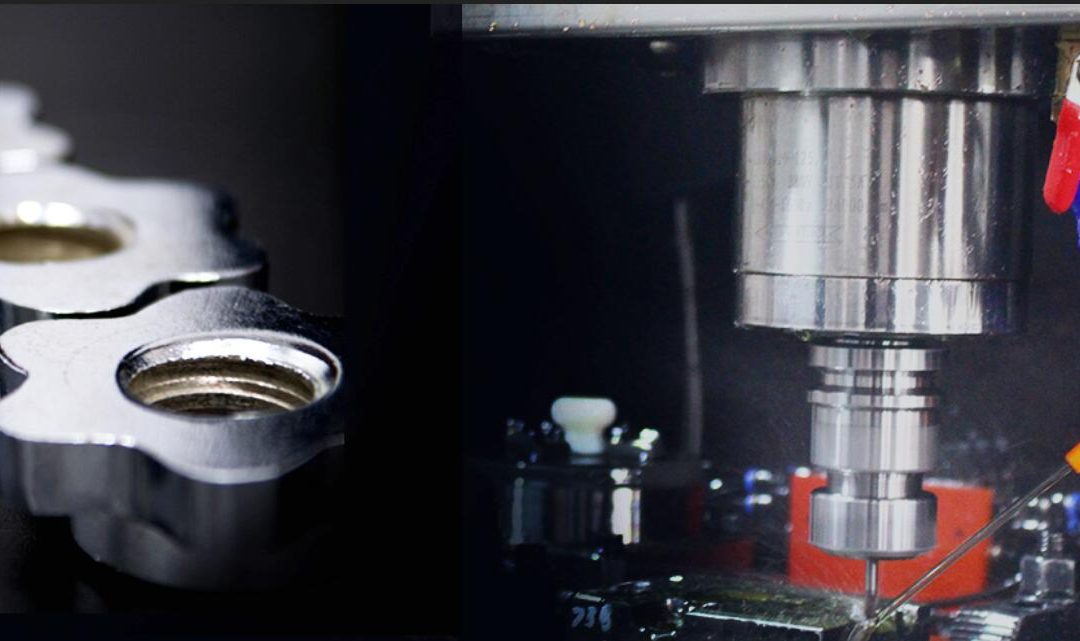

Electrical Discharge Machining (EDM) is a proven complementary method to traditional manufacturing processes like CNC milling and turning. When traditional machining methods reach their limit, electric discharge machining can be the solution. The EDM process allows...

by Danke Mold | Jun 29, 2018 | Blog

Surface Grinding is the process of removing metal by the application of abrasives from a rotating wheel. When the moving abrasive particles contact the workpiece, they are just like tiny cutting tools, each particle cutting a tiny chip from the workpiece. A good...

by Danke Mold | Jun 27, 2018 | Blog

Today we talk about wire cutting, which is also called Wire Electrical Discharge Machining. In mold making process, wire cutting is widely used for making tool inserts, pockets, mold bases, ejector and core pin holes, Contoured parting lines, and Reduced polishing. It...

by Danke Mold | Jun 25, 2018 | Blog

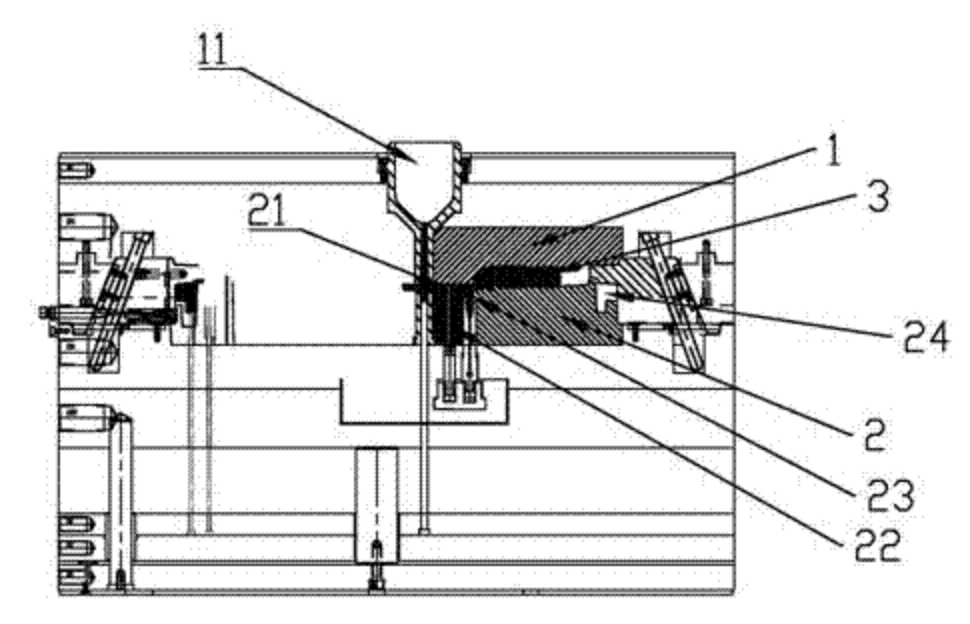

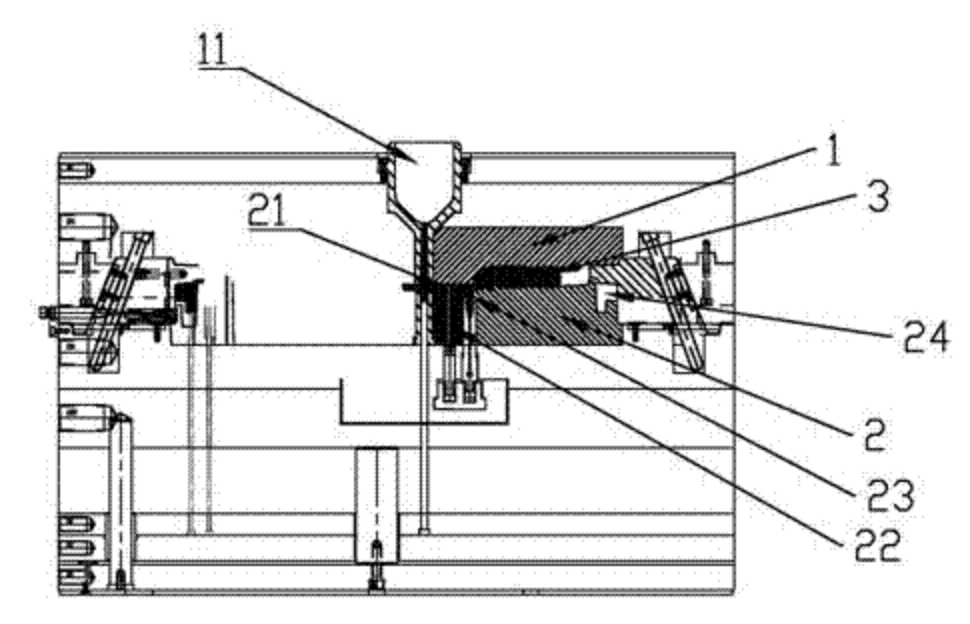

We would like to share some manufacturing knowledge about gas-assisted injection molding with you. What Is Gas-assisted Injection Molding? Gas-assisted injection molding (GAIM) is one of the innovative injection molding processes developed these 10 years....

by Danke Mold | Jun 22, 2018 | Blog

An inventor or product designer gets an idea or concept for a product. Usually the idea comes from observation of daily life or work, finds out some bugs of current product, or what people need but no product meets their requirement. An industrial designer...