by Danke Mold | Jan 9, 2025 | Rapid Tooling

Rapid Tooling refers to processes or technologies that enable the rapid manufacture of tooling components such as molds or dies. Injection Mold Tooling is a popular practice in the manufacturing sector because it enables the rapid and low-cost production of...

by Danke Mold | Dec 30, 2024 | Vacuum Casting

Silicone molding is essential to production because it produces intricate, durable items. This adaptable approach meets practical and aesthetic requirements in prototyping, consumer products, and industrial applications. Silicone molding is explained in this article,...

by Danke Mold | Nov 5, 2024 | Vacuum Casting

Modern manufacture uses flexible, high-quality silicone molding. Silicone molds are used in auto, aerospace, healthcare, and consumer. This page discusses silicone molding kinds, advantages, uses, and procedures. Molds are made by casting, compressing, or injecting...

by Danke Mold | Oct 21, 2024 | Rapid Prototyping

Project success in the ever-changing industrial business requires time and precision. Rapid tooling (RT) revolutionizes prototype-to-production. By swiftly making molds, dies, and other equipment, rapid tooling accelerates product development. The types, applications,...

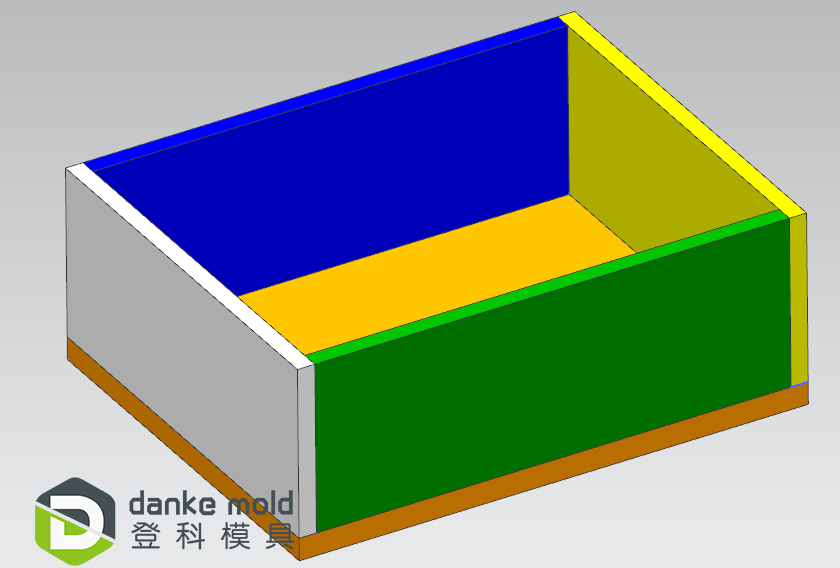

by Danke Mold | Jan 24, 2019 | Blog, Rapid Prototyping

Some practical notes about Rapid Prototyping-Sectioning When we running rapid prototype projects, which I mean includes CNC machining, SLA and vacuum casting projects, there’s various of “rules” that we should know. These “rules” are actually indications to help us to...