by Danke Mold | Oct 1, 2024 | Vacuum Casting

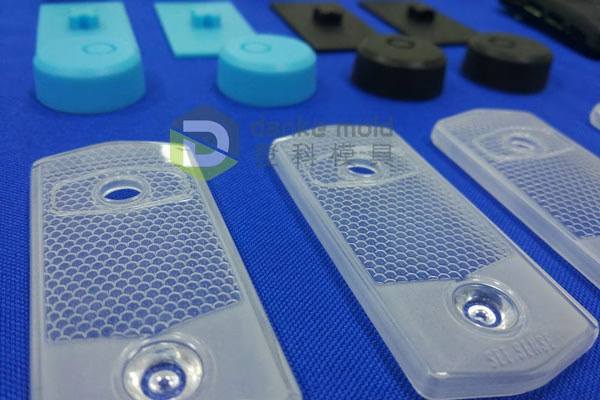

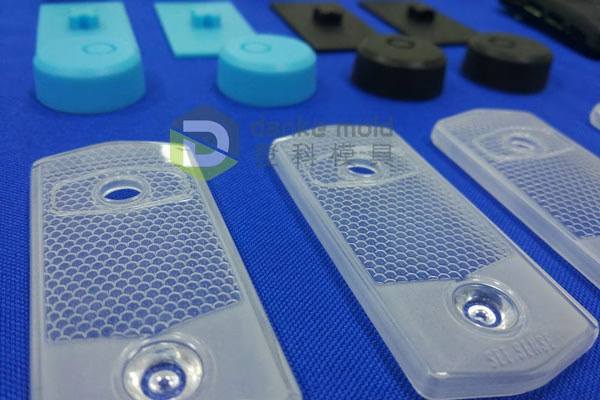

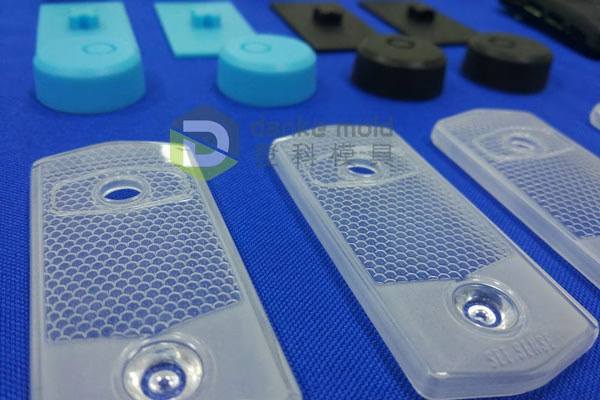

In the fast-paced world of product development, where time-to-market is critical, rapid prototyping has emerged as an essential tool for bringing ideas to life. Among the various prototyping methods available, vacuum casting stands out for its versatility,...

by Danke Mold | Sep 12, 2024 | Vacuum Casting

In rapid prototyping, where speed and precision intersect, vacuum casting stands out as a technique that can replicate intricate details and surface finishes with unparalleled accuracy. This process has become the go-to choice for designers and engineers seeking...

by Danke Mold | Sep 5, 2024 | Vacuum Casting

Vacuum casting is often hailed as a champion of prototyping, enabling designers and engineers to quickly and cost-effectively create realistic models of their product concepts. However, this versatile manufacturing process offers much more than initial prototypes....

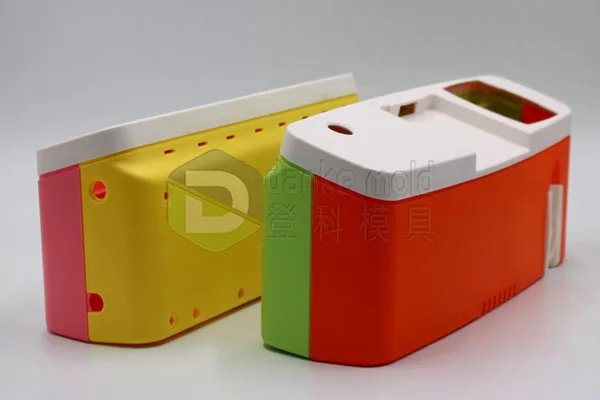

by Danke Mold | Aug 20, 2024 | Plastic Injection Molding

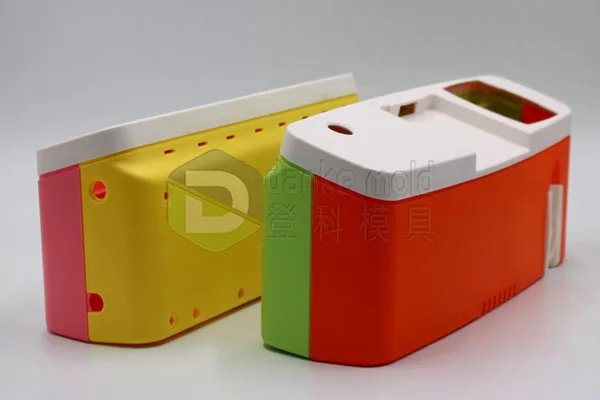

The choice of the right manufacturing process is pivotal to bringing your product vision to life. Whether you’re developing a prototype or gearing up for mass production, deciding between vacuum casting and injection molding for plastic parts can significantly...

by Danke Mold | Aug 13, 2024 | Vacuum Casting

Vacuum casting, a unique manufacturing technology, is used for high-quality prototypes and limited production runs that may be manufactured with unsurpassed precision and complexity. Nowadays, industries seeking quick and effective manufacturing solutions turn to this...