We would like to share some manufacturing knowledge about gas-assisted injection molding with you.

What Is Gas-assisted Injection Molding?

Gas-assisted injection molding (GAIM) is one of the innovative injection molding processes developed these 10 years.

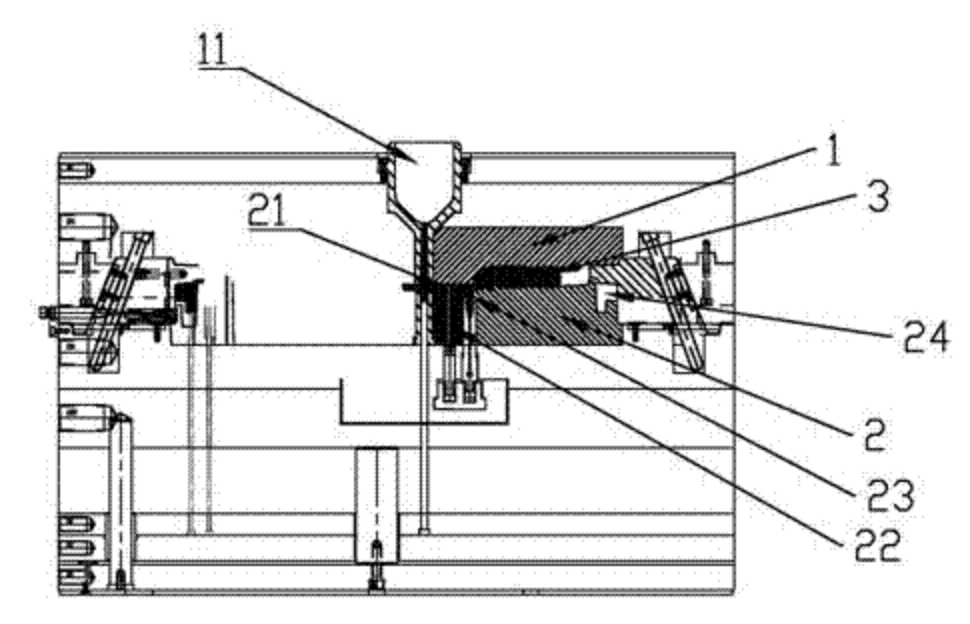

Gas assist injection molding is a low-pressure process that requires the injection of pressurized nitrogen gas into the interior of a mold. The gas flows through strategically placed gas channels to displace the material in the thick areas of the part by forming hollow sections.

Gas-assisted injection molding has mounted up to 10% of injection molding now. Despite so many advantages, the mold design and process control become more critical and difficult since this process involves dynamic interaction between two dramatically dissimilar materials flowing within complex cavities. Further, previous experience with conventional injection molding is no longer effective for this process, especially in designing the gas channel and optimizing the processing window.

Advantages of the gas-assisted injection molding process

In the gas-assisted injection molding, pressured gas displaces the polymer melt in the thicker sections of the mold cavity and leaves a polymer lay at the mold walls. This new process can substantially reduce operating expenses as well as improve product quality through reduction in residual stress. Therefore, it has come into practice as a ripe technology and has been spread extensively.

- Reducing stress and warpage

- Elimination of sink marks

- Smooth surface

- Reduced clamp tonnage

- Elimination of external runners

- Permitting different wall thickness

- Cycle time reduction

- Resin saving

If you have a plastic product with thick section, gas-assisted injection molding might be an option.

We will share as much knowledge as we can to help you understand more about manufacturing. 🙂

www.dankemold.com/ (Rapid tooling, injection molding, rapid prototyping)