In the manufacturing industry, speed is very important. The changing tastes of the consumer means that products that take a long time in the development process may never catch up with the fashion, it will likely outmode before they are launched to the market. Rapid prototyping is a good way of quickly making a model or example of a product for use in the development process.

Besides speed, rapid prototype can give you a good chance to check the visual surface finish, assembly status, function, show it at your booth in exhibition, or even test your market.. So that you can keep improving your design in this stage before going to the large quantity production.

In Danke Mold, you can make 1-50 pieces of prototypes according to your need. And we also do aluminium/soft steel tooling and molding, which is low volume production, for your to just make hundreds to thousands of parts for test the market with low cost.

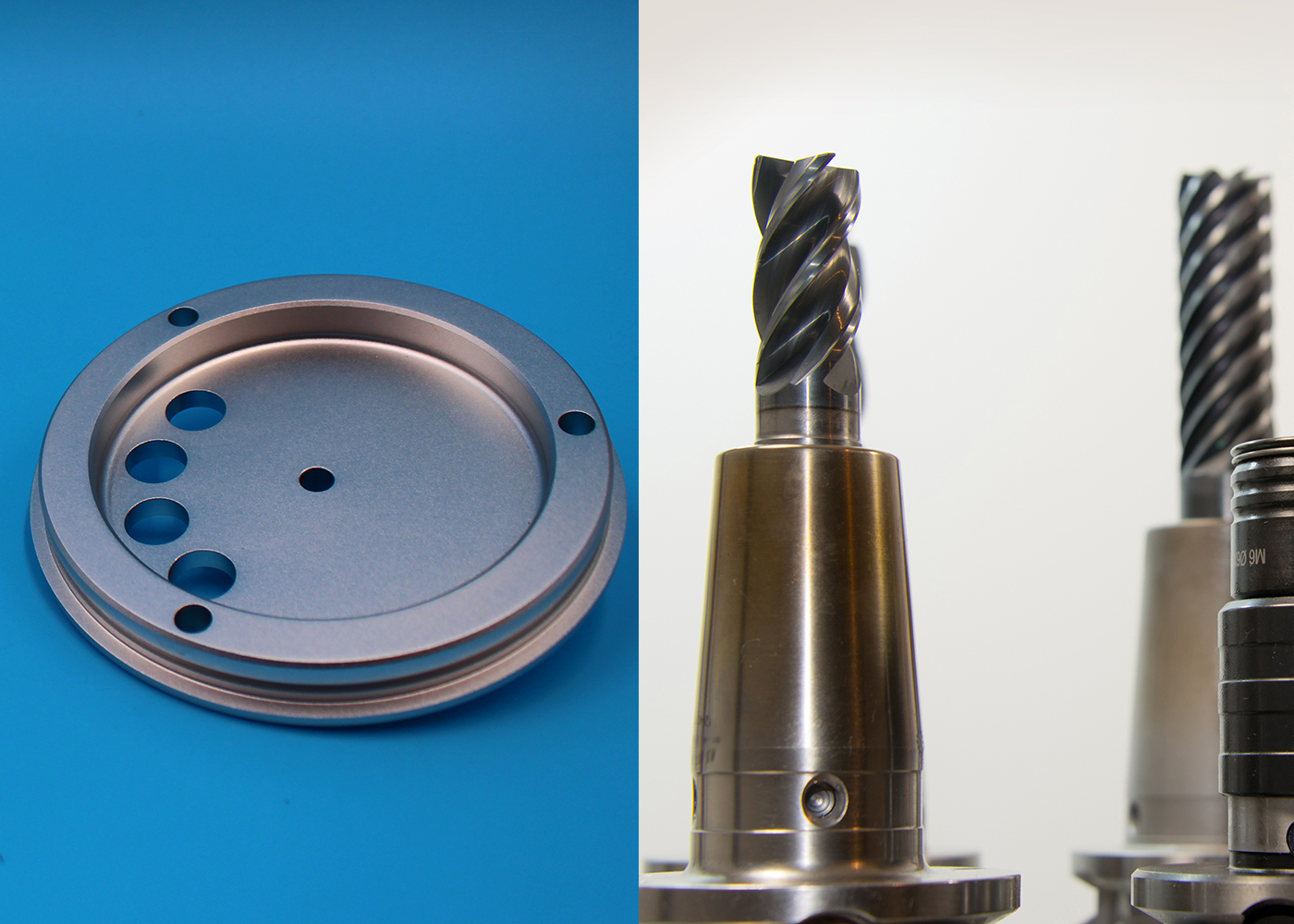

In our opinion, 3D printing, CNC machining and silicone mold vacuum casting are the most common process in rapid prototyping area..

What Types of Parts are suitable for Rapid Prototyping?

Nearly all kinds of product is a potential user of rapid prototyping services. The process uses relatively flexible and easy to work with materials like plastics, steel, aluminium, magnesium, titanium to quickly create an exact model of the part to be fabricated. The completed model can then be used for research or further development.

One example would be a housing part of a consumer electronics product. According to the size, structure, surface finish, require quantity, etc, we can make it by CNC machining, 3D printing or vacuum casting. In Danke Mold, we have professional engineer to analyze your project, and find out the most suitable and cost-effective solution to make the best part and save your cost.

Designing Parts for Rapid Prototyping.

The product designer first creates the image of the product in CAD, or computer aided design software. The data file is then loaded into the rapid prototyping system, which uses it as instructions to make the finished part. The design can be as complicated or simple as needed the finished part is usually not the final version but rather a development version or model. Once the design is finalized the final part is fabricated using more traditional techniques.