Glossary

There’s a lot of industry terms to sort through in manufacturing. Explore our glossary for quick definitions of frequently used manufacturing terms and acronyms.

ACIS

A standard computer file format for exchanging CAD data, typically from AutoCAD programs. ACIS is an acronym that originally stood for “Andy, Charles and Ian’s System.”

Additive manufacturing, 3D printing

Commonly used interchangably, additive manufacturing (3D printing) involves a CAD model or scan of an object that is reproduced, layer by layer, as a physical three-dimensional object. Stereolithography, selective laser sintering, fused deposition modeling and direct metal laser sintering are some of the commonly employed additive processes.

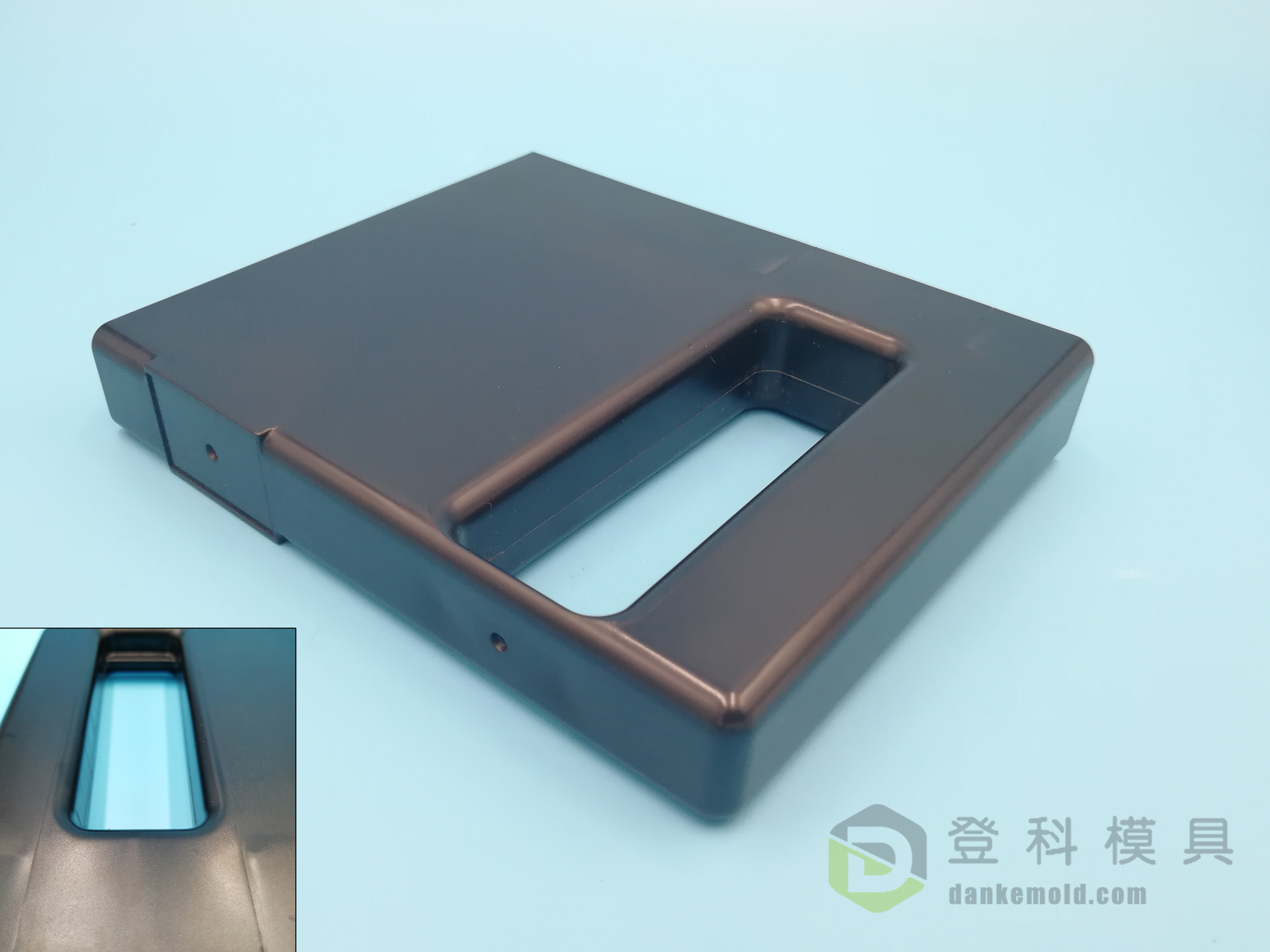

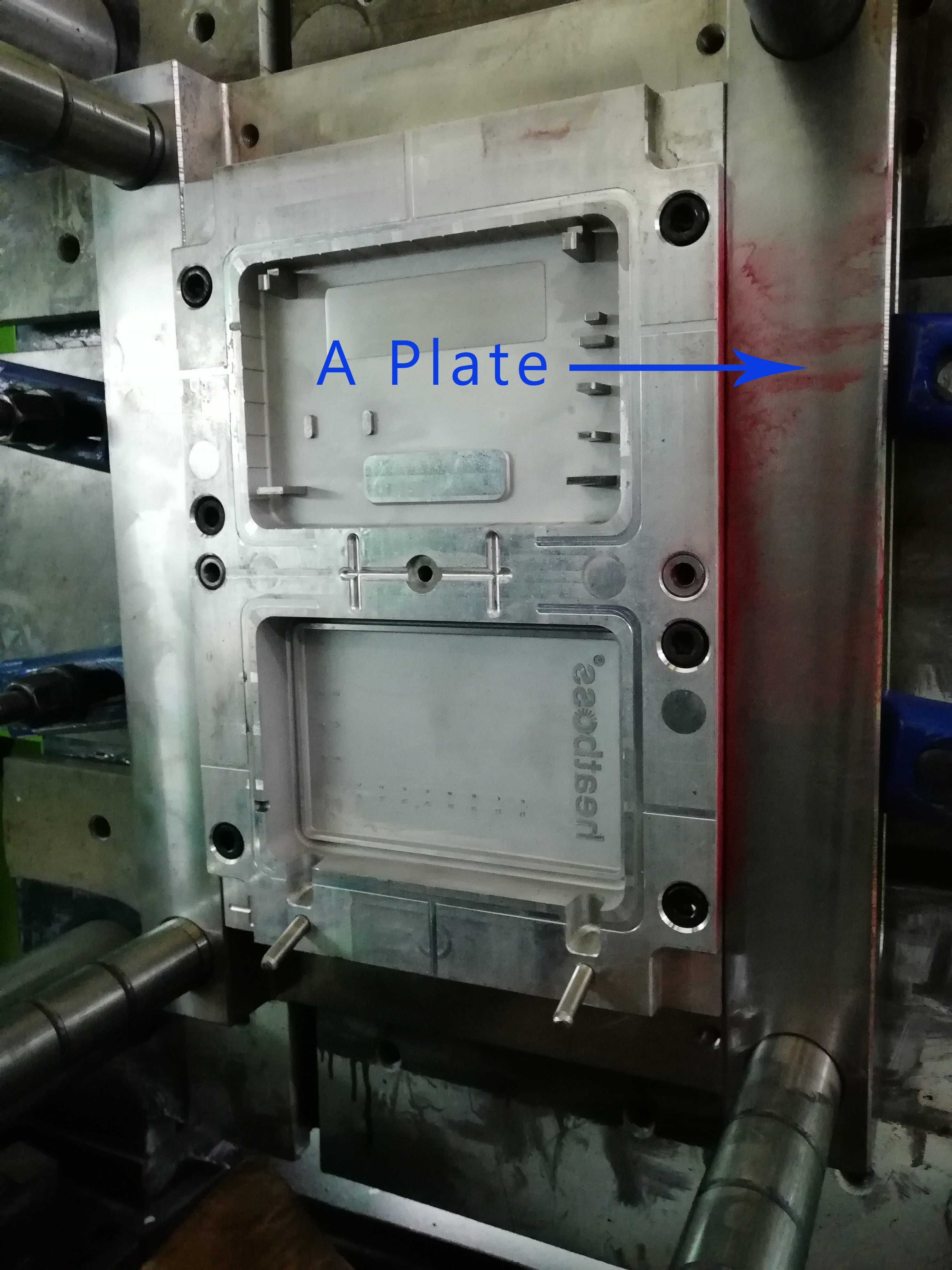

A Plate

It’s an injection molding tool component, where the cavity machined at, or inserted into. For rapid tooling and low volume injection molding, the mold maker mostly machine cavity at A plate directly, to save time and cost.

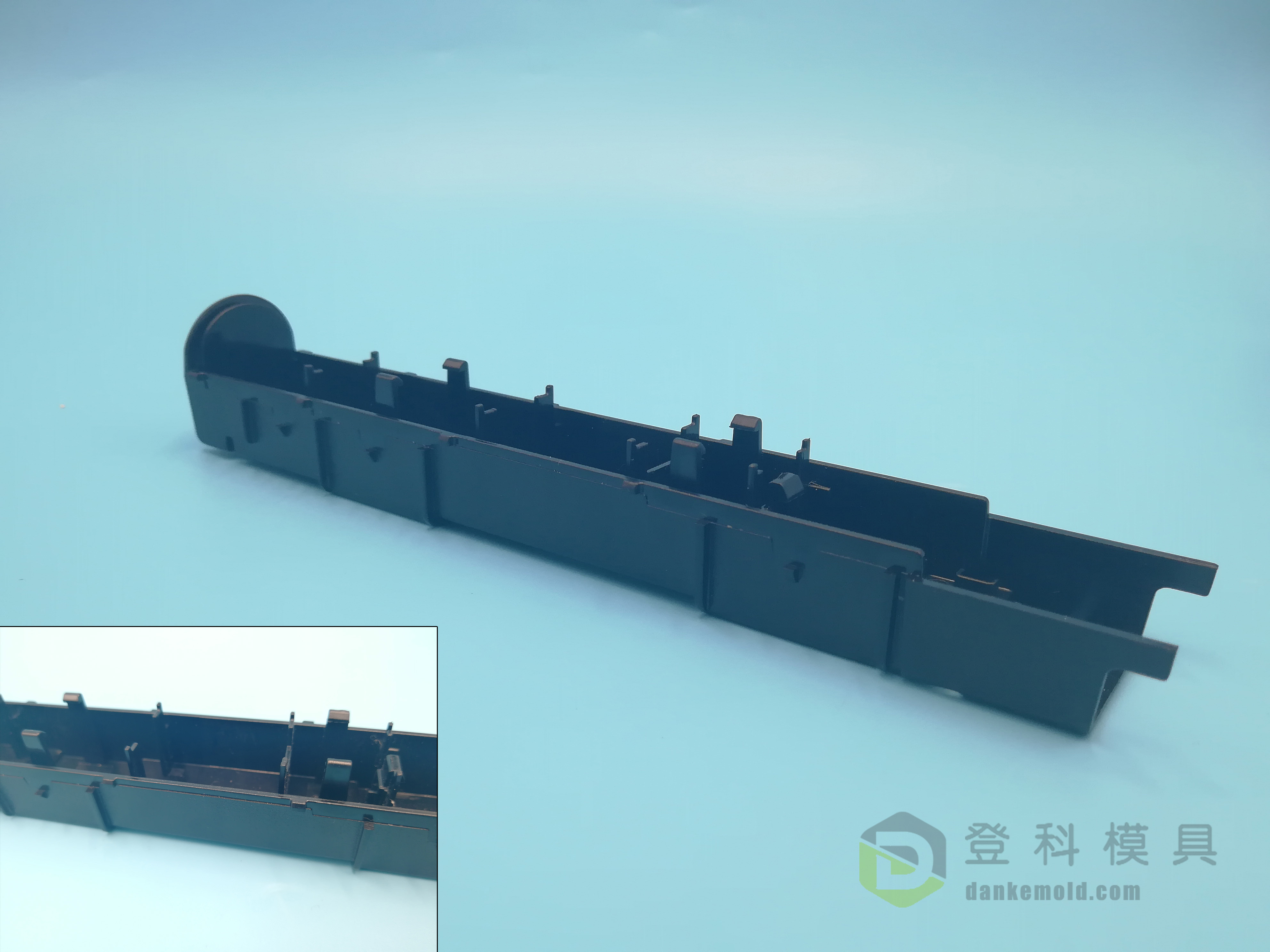

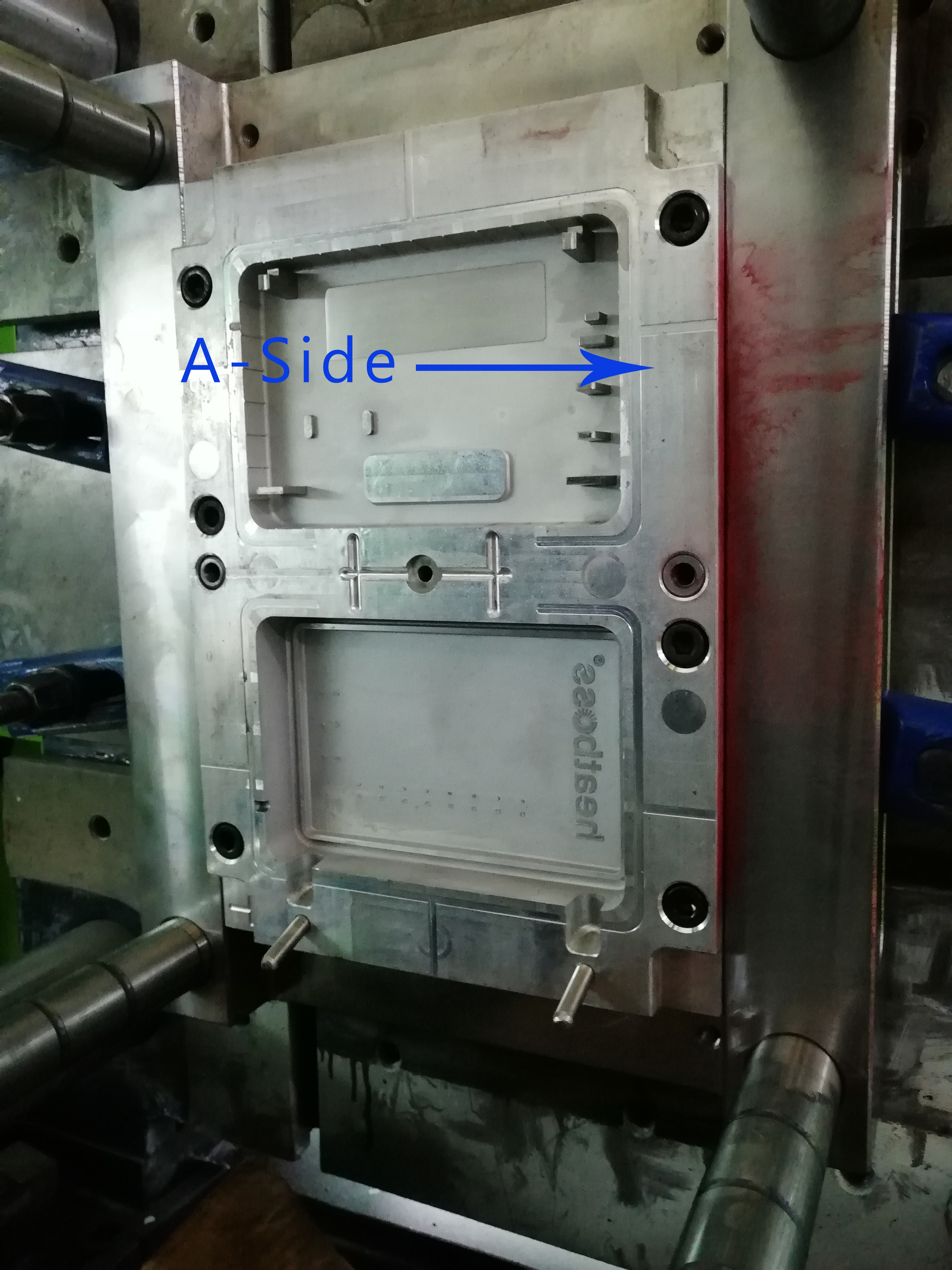

A-Side

Sometimes called the “cavity,” it is the half of the mold that usually creates the exterior of a cosmetic part. The A-side usually does not have moving parts built into it.

Angle Pin

It’s an injection mold component, which is for guiding movement of tooling sliders. It provides force for slider to de-mold.

Axial hole

This is a hole that is parallel to the axis of revolution of a turned part, but does not need to be concentric to it.

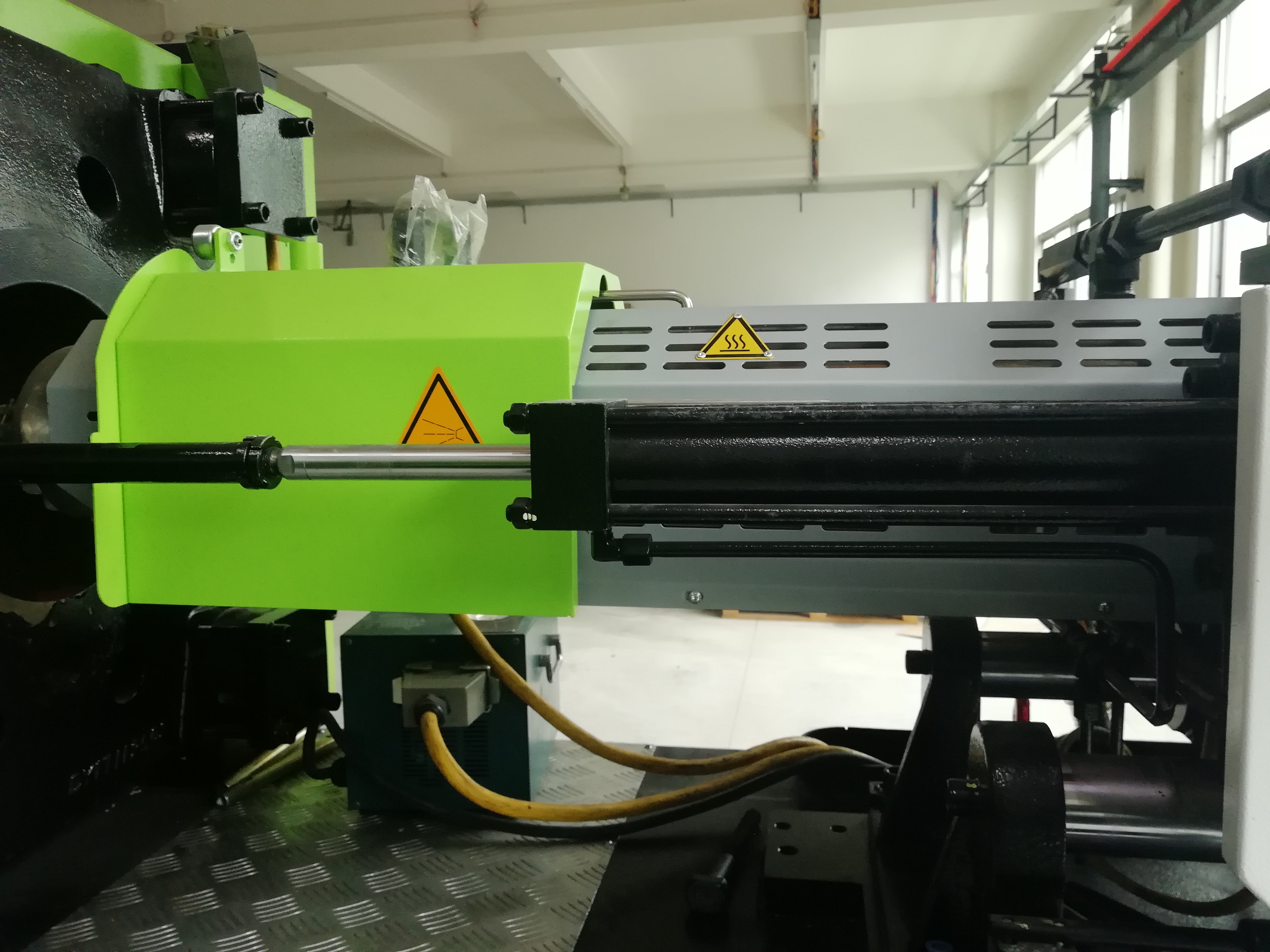

Barrel

A component of the injection-molding machine wherein the resin pellets are melted, compressed and injected into the mold’s runner system.

Bead Blasting

Using abrasives in a pressurized air blast to create a surface texture on the part.

Bevel

Also known as a “chamfer,” it is a flat truncated corner.

Blow Molding

A method of molding in which a parison(hollow tube) is forced into the shape of mold cavity by internal air pressure.

Blush

A cosmetic imperfection that is created where the resin is injected into the part, usually visible as a blotchy discoloration on the finished part at the site of the gate.

Boss

A raised stud feature that is used to engage fasteners or support features of other parts passing through them.

Bridge tool

A temporary or interim mold made for the purpose of making production parts until a high-volume production mold is ready.

B-side

Sometimes called the “core,” it is the half of the mold where ejectors, side-action cams and other complex components are located. On a cosmetic part, the B-side usually creates the inside of the part.

Build platform

The support base on an additive machine where parts are built. The maximum build size of a part is dependent on the size of a machine’s build platform. Many times a build platform will house a number of different parts of varying geometries.

Bumpoff

A feature in the mold with an undercut. To eject the part, it must bend or stretch around the undercut.

CAD

Computer-aided design.

Cam

A portion of the mold that is pushed into place as the mold closes, using a cam-actuated slide. Typically, side actions are used to resolve an undercut, or sometimes to allow an undrafted outside wall. As the mold opens, the side action pulls away from the part, allowing the part to be ejected. Also called a “side-action.”

Cavity

The void between the A-side and B-side that is filled to create the injection-molded part. The A-side of the mold is also sometimes called the cavity.

Chamfer

Also known as a “bevel,” it is a flat truncated corner.

Clamp force

The force required to hold the mold shut so resin cannot escape during injection. Measured in tons, as in “we have a 700 ton press.”

Colorant

An additive mixed into a plastic resin to give a color th the material. In low volume injection molding production, We use pigment powder. While in high volume production. colorant pellet will be applied.

Compression Molding

A technique used in thermoset molding in which a molding compound is placed in an open mold cavity and then the mold is closed until heat and pressure have allowed the material to cure.

Continuous Use Temperature

The temperature at which a material will perform reliably. It’s a very important consideration before we choose a material for injection molded parts.

Contoured Pins

Ejector pins with the ends shaped to match a sloping surface on the part.

Core

A portion of the mold that goes inside a cavity to form the interior of a hollow part. Cores are normally found on the B-side of a mold, thus, the B-side is sometimes called the core.

Core Pins

Pins which are inserted into the mold cavity surface to form either blind or through holes in the molded part.

Core-cavity

A term used to describe a mold created by mating A-side and B-side mold halves.

Cycle time

The time it takes to make one part including the closing of the mold, the injection of the resin, the solidification of the part, the opening of the mold and the ejection of the part.

DFM

DFM,the abbreviation of Design for Manufacturing. It’s a product design review process for ensuring the part makeable and with quality. We usually prepare a DFM for checking the surface finish, parting line, gate position, ejection method, draft, wall thickness, undercuts and maybe some other mold making issues or concerns, before an injection molding mold start building.

Direct metal laser sintering (DMLS)

DMLS employs a fiber laser system that draws onto a surface of atomized metal powder, welding the powder into a solid. After each layer, a blade adds a fresh layer of powder and repeats the process until a final metal part is formed.

Direction of pull

The direction the mold surfaces move when they are moving away from the part surfaces, either when the mold opens or when the part ejects.

Draft

A taper applied to the faces of the part that prevent them from being parallel to the motion of the mold opening. This keeps the part from being damaged due to the scraping as the part is ejected out of the mold.

Drying of plastics

Many plastics absorb water and must be dried prior to injection molding to ensure good cosmetics and material characteristics.

Durometer

A measure of a material’s hardness. It is measured on a numeric scale ranging from lower (softer) to higher (harder).

Edge gate

An opening aligned with the parting line of the mold where resin flows into the cavity. Edge gates are typically placed on an outside edge of the part.

EDM

Electric discharge machining. A moldmaking method which can create taller, thinner ribs than milling, text on top of ribs and square outside edges on parts.

Ejection

The final stage of the injection-molding process where the completed part is pushed from the mold using pins or other mechanisms.

Ejector Pins

Ejector pins expedite removal of parts by having a mechanically operated pin push the molded part out of the mold cavity.

Elongation at break

How much the material can stretch or deform before breaking. This property of LSR allows for some difficult parts to be surprisingly removed from molds. For example, LR 3003/50 has an elongation at break of 480 percent.

End mill

A cutting tool that is used to machine a mold.

ESD

Electro static discharge. An electrical effect that may necessitate shielding in some applications. Some special grades of plastic are electrically conductive or dissipative and help prevent ESD.

Extrusion

The forcing of a melt through a shaping die under pressure.

Family mold

A mold where more than one cavity is cut into the mold to allow for multiple parts made of the same material to be formed in one cycle. Typically, each cavity forms a different part number. See also “multi-cavity mold.”

Filler

In injection molding an inert substance added to plastic primarily to reduce the cost; it may also improve some physical properties.

Fillet

A curved face where a rib meets a wall, intended to improve the flow of material and eliminate mechanical stress concentrations on the finished part.

Finish

A specific type of surface treatment applied to some or all faces of the part. This treatment can range from a smooth, polished finish to a highly contoured pattern that can obscure surface imperfections and create a better looking or better feeling part.

Flame Retardant

Chemicals compounded into a resin formulation in order to reduce the tendency of the material to burn. It’s often used at injection molded part.

Flash

Resin that leaks into a fine gap in the parting lines of the mold to create an undesired thin layer of plastic or liquid silicone rubber.

Flow marks

Visible indications on the finished part that show the flow of plastic within the mold prior to solidification.

Food grade

Resins or mold release spray that are approved for use in the manufacture of parts that will contact food in their application.

Fused deposition modeling (FDM)

With FDM, a wire coil of material is extruded from a print head into successive cross-sectional layers that harden into three-dimensional shapes.

Gate

The orifice through which the melt resin enters the cavity in an injection or transfer mold. Gate position may affect the cosmetic. No matter at rapid tooling or produiction tool, it always need thorough discussion befor tool building.

GF

Glass-filled. This refers to a resin with glass fibers mixed into it. Glass-filled resins are much stronger and more rigid than the corresponding unfilled resin, but are also more brittle.

Gusset

A triangular rib that reinforces areas such as a wall to a floor or a boss to a floor.

Hot tip gate

A specialized gate that injects the resin into a face on the A-side of the mold. This type of gate doesn’t require a runner or sprue.

Hardness

Measure of the resistance to localized plastic deformation for a material.

IGES

Initial Graphics Exchange Specification. It is a common file format for exchanging CAD data. Protolabs can use IGES solid or surface files to create molded parts.

Injection

The act of forcing molten resin into the mold to form the part.

Injection Molding

The process of melting or plasticating a polymeric material and forcing it from a cylinder into a cavity of a specific shape for hardening.Rapid Injection Molding is together with rapid tooling for low volume production.

Insert

A portion of the mold that is installed permanently after machining the mold base, or temporarily between mold cycles.

Jetting

Flow marks caused by the resin entering a mold at high speed, typically occurring near a gate.

Knit lines

Also known as “stitch lines” or “weld lines,” and when multiple gates are present, “meld lines.” These are imperfections in the part where separated flows of cooling material meet and rejoin, often resulting in incomplete bonds and/or a visible line.

Layer thickness

The precise thickness of a single additive layer that can reach as small as microns thin. Often, parts will contain thousands of layers.

Lifter

It’s a tooling component, to provide side movement for internal undercuts. It’s for forming the clips, internal undercuts. For rapid tooling and low volume injection molding, sometime we also use manual inserts instead to save time and tooling cost.

LIM

Liquid injection molding, which is the process used in the molding of liquid silicone rubber.

Live tooling

Mill-like machining actions in a lathe where a rotating tool removes material from stock. This allows for the creation of features like flats, grooves, slots, and axial or radial holes to be created within the lathe.

Living hinge

Very thin section of plastic used to connect two parts and keep them together while allowing them to open and close. They require careful design and gate placement. A typical application would be the top and bottom of a box.

Low volume manufacturing

It combines different manufacturing technics for low volume custom needs. It decreases the time and save the cost for low volume custom needs, by without complicate tooling. It is not often used for large scale and long term operations for a part. At plastic parts making, it includes the processes: SLA, vacuum casting, CNC machining, rapid tooling and injection molding.

LSR

Liquid silicone rubber.

Lubricant

An additive used to improve the processiblity and appearance of plastics, during injection molding.

Manual insert

It’s a hand-loaded tooling component, for forming different kinds of undercuts and complicate part structure. It’s widely used at rapid tooling and low volume injection molding production.

Medical grade

Resin that may be suitable for use in certain medical applications.

Meld lines

Occurs when multiple gates are present. These are imperfections in the part where separated flows of cooling material meet and rejoin, often resulting in incomplete bonds and/or a visible line.

Metal safe

A change to the part design that requires only the removal of metal from the mold to produce the desired geometry. Typically most important when a part design is changed after the mold has been manufactured, because then the mold can be modified rather than entirely re-machined. It is also commonly called “steel safe.”

Mold Insert

A removable insert which is placed in the mold cavity surface to mold a part feature. Mold inserts are used to achieve multiple parts from a set of mold tooling.

Molded-in Inserts

Molded-in inserts generally require that the mold operator manually place the inserts into the mold when the mold is open.This operation generates operator safety problems for the part molder. To assure operator safety the molder must reduce the molding cycle rate, hence increase the part cost.It’s often used in rapid tooling and low volume plastic injection molding production.

Mold release spray

A liquid applied to the mold as a spray to facilitate the ejection of parts from the B-side. It is typically used when the parts are difficult to eject because they are sticking to the mold.

Mold Trial

It’s the final process of mold making. A technician set up the mold at an injection molding machine, and try to run the mold for samples or pilot production with specified material. For a rapid injection tool, it takes about 2-3 mold trials before final sample approval.

Movable Side Core

Parts which require undercuts or holes that are not in line with the injection mold movement are made in molds having mechanically operated side cores.

Multi-Cavity Mold

Multiple parts are molded simultaneously through the uses of multiple cavities in a single injection mold.

Net shape

The final desired shape of a part; or a shape that does not require additional shaping operations before use.

Nozzle

The tapered fitting on the end of the barrel of the injection-molding press where the resin enters the sprue.

On-axis hole

This is a hole that is concentric to the axis of revolution of the turned part. It is simply a hole on the end of a part and in the center.

Overflow

A mass of material away from the part, typically at the end of fill, connected by a thin cross-section. The overflow is added to improve part quality and is removed as a secondary operation.

Packing

The practice of using increased pressure when injecting a part to force more plastic into the mold. This is often used to combat sink or fill problems, but also increases the likelihood of flash and may cause the part to stick in to the mold.

Parasolid

A file format for exchanging CAD data.

Part A/Part B

LSR is a two-part compound; these components are kept separate until the LSR molding process begins.

Parting line

Parting line is the edge at the largest cross-section of an injection molded part. It separates tooling cavity, core, lifter, sliders and manual inserts. As it may affect the cosmetic and assembly, mold maker normally will confirm this with designer or engineer before mold making.

Pickouts

A mold insert that remains stuck to the ejected part and has to be pulled out of the part and placed back into the mold before the next cycle.

Pin-point Gate

A gating technique used to facilitate an automatic degating operation which decreases the injection molding cycle time. This type of gate tends to break reinforcing fibers and generally, tolerances are not as accurate as other gating techniques.(See Gate for illustration.)

Plasticizer

At injection molding production a chemical agent added to plastic compositions to make them softer and more flexible.

Plastic Deformation

Deformation that remains after the load causing it is removed. Injection Molded part usually would need this consideration.

PolyJet

PolyJet is a 3D printing process where small droplets of liquid photopolymer are sprayed from multiple jets onto a build platform and cured in layers that form elastomeric parts.

Porosity

Undesired voids included in a part. Porosity can manifest in many sizes and shapes from many causes. Generally, a porous part will be less strong than a fully dense part.

Post gate

A specialized gate that uses a hole that an ejector pin passes through to inject resin into the mold cavity. This leaves a post vestige that usually needs to be trimmed.

Press

An injection molding machine.

Quality Control

Processes and procedures for measuring and recording numerical and subjective parameters affecting the visual and physical attributes of a manufactured part.

Quenching

This is the rapid cooling of a workpiece to achieve specific material properties such as hardness. Normally part of the heat treatment process of metal used for mold tooling.

Radial hole

This is a hole formed by live tooling that is perpendicular to the axis of revolution of a turned part, and could be considered a side hole. The center line of these holes are not required to intersect the axis of revolution.

Radiused

An edge or vertex that has been rounded. Typically, this occurs on part geometries as a natural result of the Protolabs’ milling process. When a radius is intentionally added to an edge on a part, it is referred to as a fillet.

Ram

A hydraulic mechanism that pushes the screw forward in the barrel and forces resin into the mold.

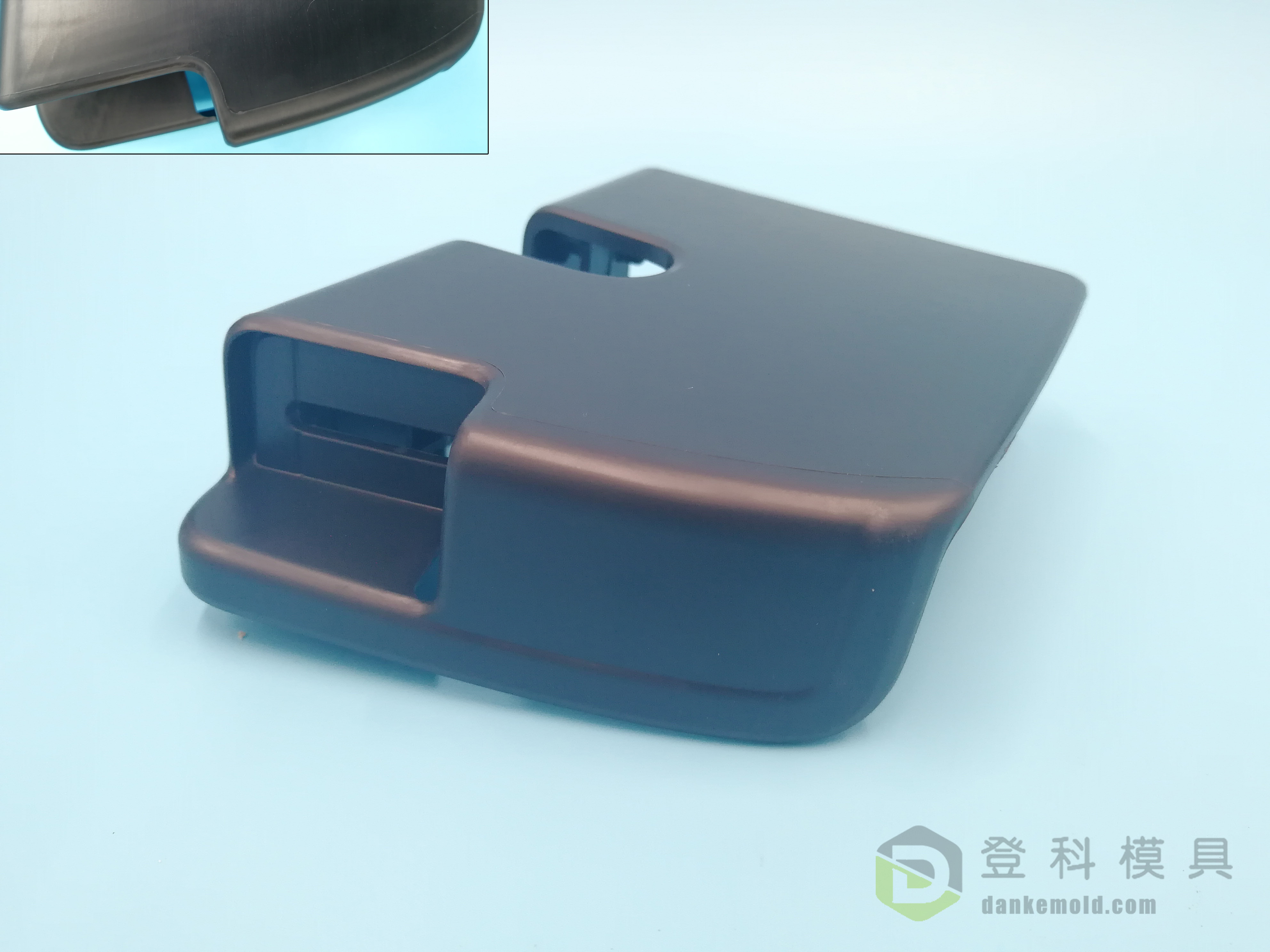

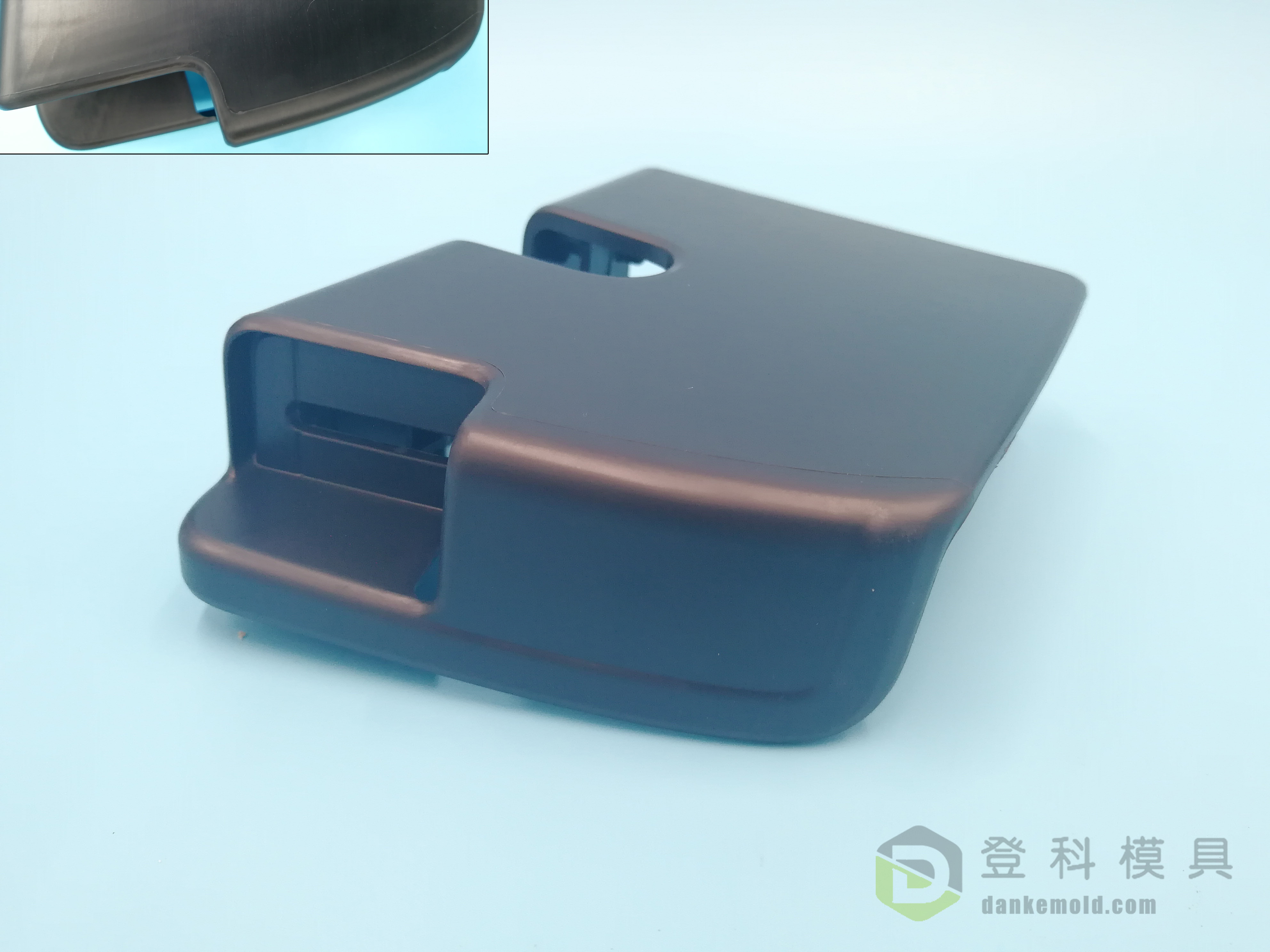

Rapid Tooling

In Danke Mold Ltd, we mostly meant rapid injection molding tool. It denotes making plastic injection mold and produce plastic injection molded parts with a slim timeline. We use aluminum insert, soft steel insert (P20, 50#, NAK 80 steel), simplified tooling structure (manual inserts), common use mold components (mold base, ejection plate), and post process to decrease the time and the cost of the mold and product. It’s widely used for prototype making, bridge tooling, material testing, functional testing, market testing and low volume production of plastic injection molding.

Reaction Injection Molding

The process involving the mixing of two or more streams of highly reactive liquid components in a small chamber followed by rapid flow of this mixture directly into a injection mold cavity.

Recess

n indentation in the plastic part caused by the impact of the ejector pins.

Recovery

Index of the ability for a material to recover from deformation. It’s a very important property for rubber parts.

Reinforced resin

Refers to base resins with fillers added for strength. They are particularly susceptible to warp because the fiber orientation tends to follow flow lines, resulting in asymmetric stresses. These resins are typically harder and stronger but also more brittle (e.g., less tough).

Relaxation

Rate of reduciton of stress in a material due to creep.

Resin

A generic name for chemical compounds that, when injected, form a plastic part. Sometimes just called “plastic.”

Resolution

The level of printed detail achieved on parts built through additive manufacturing. Processes like stereolithography and direct metal laser sintering allow for extremely fine resolutions with the smallest of features.

Rib

A thin, wall-like feature parallel to the mold opening direction, common on plastic parts and used to add support to walls or bosses.

Rotational MOlding

A process for making hollow parts by charging a mold with resin and allowing it to rotate in one or two planes inside of an oven.

Runner

The channel which connects the sprue with the gate to the mold cavity in an injection or transfer mold.

Screw

A device in the barrel that compacts resin pellets to pressurize and melt them prior to injection.

Selective laser sintering (SLS)

During the SLS process, a CO2 laser draws onto a hot bed of thermoplastic powder, where it lightly sinters (fuses) the powder into a solid. After each layer, a roller lays a fresh layer of powder on top of the bed and the process repeats.

Shear

The force between layers of resin as they slide against each other or the surface of the mold. The resulting friction causes some heating of the resin.

Short-shot

In injection molding,failure to completely fill the mold of molten resin.At rapaid tooling and prototype injection molding, we suggest enough wall thickness before mold making, to save cost and deliver on time.

Shrink

The change in part size as it cools during the molding process. This is anticipated based on material manufacturer recommendations and built into the mold design before manufacturing.

Shrinkage

It’s a very critical factor at injection mold design.Shrinkage is the difference between dimensions of the mold and the corresponding dimensions of the molded part. Shrinkage affects dimensions, warpage, residual stress and moldability. The amount of shrinkage varies with the material,the part design and the the curing cycle.

Shutoff

A feature that forms an internal through-hole in a part by bringing the A-side and B-side in contact, preventing the flow of resin into the through-hole.

Side-action

A portion of the mold that is pushed into place as the mold closes, using a cam-actuated slide. Typically, side-actions are used to resolve an undercut, or sometimes to allow an undrafted outside wall. As the mold opens, the side action pulls away from the part, allowing the part to be ejected. Also called a “cam.”

Sink

Dimples or other distortion in the surface of the part as different areas of the part cool at different rates. These are most commonly caused by excessive material thickness.

Slider

It’s a tooling component, to provide side movement for external undercuts. It’s for forming the side holes, side windows, external profile with undercuts, of an injection molded part. For raping tooling, sometime we use manual inserts instead to save time and tooling cost.

Splay

Discolored, visible streaks in the part, typically caused by moisture in the resin.

Split Cavity Injection Mold

Split cavity molds are used for parts which have projections, undercuts and holes that are not in line with the mold movement. The cavity is divided into two or more sections which are seated in a tapered housing to permit separation from the injection molded part.

Sprue

The opening through which the melted polymer enters the plustic injection mold and leads to the runner system in injection and transfer molding.

Steel pins

A cylindrical pin for formatting high-aspect-ratio, small-diameter holes in a part. A steel pin is strong enough to handle the stress of ejection and its surface is smooth enough to release cleanly from the part without draft.

Steel safe

Also known as “metal safe” (the preferred term when working with aluminum molds). This refers to a change to the part design that requires only the removal of metal from the mold to produce the desired geometry. Typically most important when a part design is changed after the mold has been manufactured, because then the mold can be modified rather than entirely re-machined.

STEP

Stands for Standard for the Exchange of Product Model Data. It is a common format for exchanging CAD data.

Stereolithography (SL)

SL uses an ultraviolet laser focused to a small point to draw on the surface of a liquid thermoset resin. Where it draws, the liquid turns to solid. This is repeated in thin, two-dimensional cross-sections that are layered to form complex three-dimensional parts.

Sticking

A problem during the ejection phase of molding, where a part becomes lodged in one or the other half of the mold, making removal difficult. This is a common issue when the part is not designed with sufficient draft.

Stitch lines

Also known as “weld lines” or “knit lines,” and when multiple gates are present, “meld lines.” These are imperfections in the part where separated flows of cooling material meet and rejoin, often resulting in incomplete bonds and/or a visible line.

STL

Originally stood for “STereoLithography.” It is a common format for transmitting CAD data to rapid prototyping machines and is not suitable for injection molding.

Straight-pull mold

A mold that uses only two halves to form a cavity that resin is injected into. Generally, this term refers to molds with no side-actions or other special features used to resolve undercuts.

Stripper Plate

At mold making, stripper plates are used for thin-walled parts where ejector pins might be damaging.

Submarine Gate(Tunnel Gate)

A gating technique used to facilitate automatic injection degating operation which decreases the mold cycle time. The gate is physically located below the parting line in the mold. This type of gate tends to break reinforcing fibers and generally, tolerances are not as accurate as other gating techniques.

Tab gate

An opening aligned with the parting line of the mold where resin flows into the cavity. These are also referred to as “edge-gates” and are typically placed on an outside edge of the part.

Tear Strip

A feature added to the mold that will be removed from the part after molding to aid in creating a crisp end on the part. This is often done in conjunction with an overflow to improve the final part quality.

Texture

A specific type of surface treatment applied to some or all faces of the part. This treatment can range from a smooth, polished finish to a highly contoured pattern that can obscure surface imperfections and create a better looking or better feeling part.

Thermoforming

A process of forming a thermoplastic sheet into a product by the application of heat and pressure. Forming pressure may be developed by vacuum (atmospheric pressure), compressed air, or mating matched molds.

Thermoplastic

A linear polymer which will repeatedly soften by heat and harden by cooling. It’s widely used in plastic injection molding for volume production.

Thermoset

A polymeric resin which changes irreversibly into a relatively infusable material through the formation of a covalently crosslingked, thermally stable network. It’s widely used in vacuum casting for prototype making and low volume production.

Thermoplastic Elastomer(TPE or TPR)

A thermoplastic material which at room temperature stretches, under low stress, to at least twice its length and snaps back to the original length upon release of stress. It’s often used for producing gasket, soft components of over molding in injection molding production.

Thermoset Elastomer(TSE)

A thermoset material which at room temperature stretches, under low stress, to at least twice its length and snaps back to the original length upon its release. The typical usageis rubber nipple and pacifiers in volume production.

Toughness

The extent to which a material absorbs energy without fracture.

Tunnel gate

A gate that is cut through the body of one side of the mold to create a gate that does not leave a mark on the exterior face of the part.

Turning

During the turning process, rod stock is rotated in a lathe machine while a tool is held against the stock to remove material and create a cylindrical part.

Undercut

A portion of the part that shadows another portion of the part, creating an interlock between the part and one or both of the mold halves. An example is a hole perpendicular to the mold opening direction bored into the side of a part. An undercut prevents the part from being ejected, or the mold from opening, or both.

Vents

A channel approximately 0.025 X 5 mm which allows entrapped air to escape the mold pockets to the outside of the mold. Vents prevent burning of the plastic part caused by excessive heating of the pressurized air pockets during injection molding.

Vestige

After molding, the plastic runner system (or in the case of a hot tip gate, a small dimple of plastic) will remain connected to the part at the location of the gate/s. After the runner is trimmed off (or the hot tip dimple is trimmed), a small imperfection called a “vestige” remains on the part.

Wall

A common term for the faces of a hollow part. Consistency in wall thickness is important.

Wrap

The curving or bending of a part as it cools that results from stresses as different portions of the part cool and shrink at different rates. Parts made using filled resins may also warp due to the way the fillers align during resin flow. Fillers often shrink at different rates than the matrix resin, and aligned fibers can introduce anisotropic stresses.

Weld Line

A visible mark on a injection molded part due to the meeting of two flow fronts during the molding operation which can cause loss of strength of the material. It open happen at frame, area around a hole or a window of a injection molded part.

Wireframe

A type of CAD model consisting only of lines and curves, in 2D or 3D. Wirefame models are not suitable for rapid injection molding.

X-Axis

One of three primary axes of movement in a three-dimensional X-Y-Z coordinate system. Generally assumed to be horizontal to the viewer’s reference.

XRF

X-Ray Fluorescence. Non-destructive analytical test for determining a material’s composition by bombarding the surface with high-energy x-rays and reading the resulting emitted spectra, which is unique for all material types.

Y-Axis

One of three primary axes of movement in a three-dimensional coordinate system. Generally considered to be vertical to the viewer’s reference.

Yield Strength

Indication of maximum stress that can be developed in a material without causing plastic deformation.

Z-Axis

One of three primary axes of movement in a three-dimensional coordinate system. Generally considered to be towards or away from the viewer’s reference.